Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Fuel pump control circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hand–held tester:

1 Perform active test by hand–held tester(operation of circuit opening relay)

- Connect the hand–held tester to the dlc3.

- turn the ignition switch on and push the hand–held tester main switch on.

- select the item ”diagnosis / enhanced obd ii / active test / fuel pump / spd”.

- check the relay operation while operating it with the hand–held tester.

Standard: operating noise can be heard from the relay.

2 Inspect ecm power source circuit

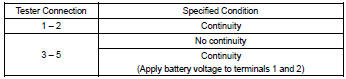

3 Inspect circuit opening relay

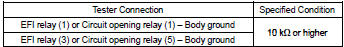

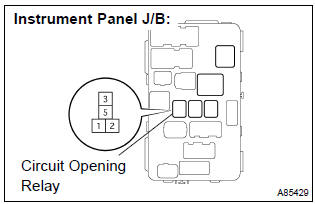

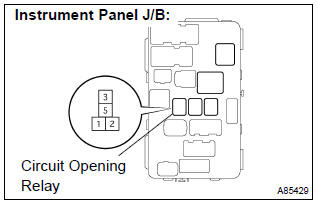

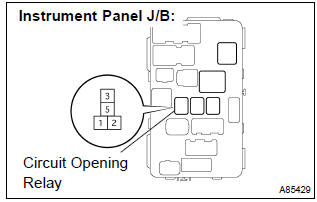

- Remove the circuit opening relay from the instrument panel j/b.

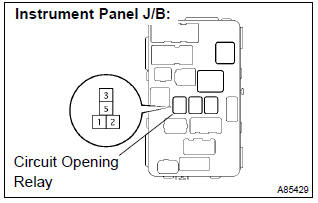

- check for continuity in the circuit opening relay.

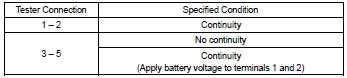

Standard:

- Reinstall the circuit opening relay.

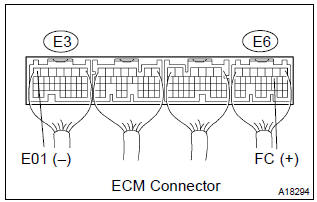

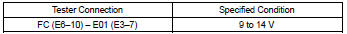

4 Inspect ecm(fc voltage)

- Turn the ignition switch on.

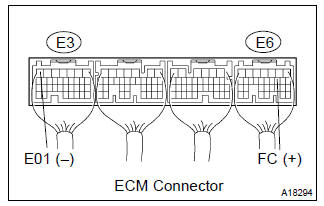

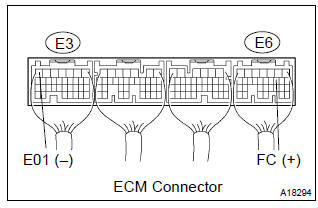

- measure the voltage between the terminals of the e3 and e6 ecm connectors.

Standard:

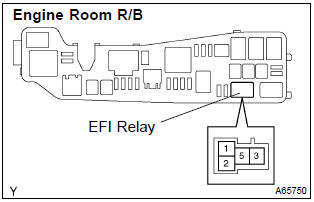

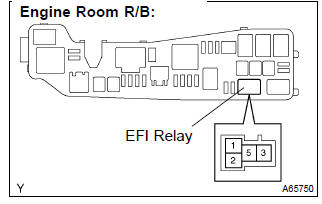

5 Check harness and connector(efi relay – circuit opening relay)

- Remove the efi relay from the engine room r/b.

- remove the circuit opening relay from the instrument panel j/b.

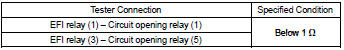

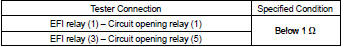

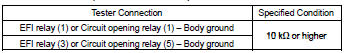

- check the resistance between the wire harness side connectors.

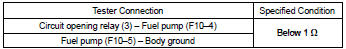

Standard (check for open):

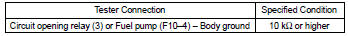

Standard (check for short):

- Reinstall the circuit opening relay.

- reinstall the efi relay.

Replace ecm

6 Inspect fuel pump

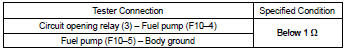

7 Check harness and connector(circuit opening relay – fuel pump, fuel pump – body ground)

- Remove the circuit opening relay from the instrument panel j/b.

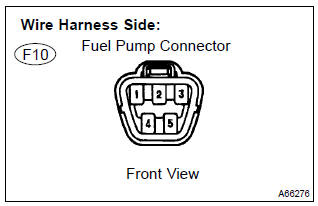

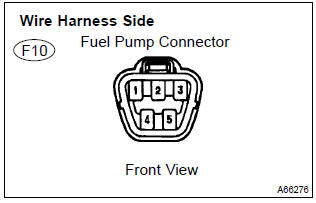

- disconnect the f10 fuel pump connector.

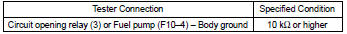

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the fuel pump connector.

- reinstall the circuit opening relay.

Replace ecm

Obd ii scan tool (excluding hand–held tester):

1 Check operation of fuel pump

- Turn the ignition switch on.

- connect between terminals fc and e01 of the ecm connector.

- check for fuel pressure in the fuel inlet hose when it is

pinched off.

Result: there is pressure in fuel inlet hose.

Hint

: at this time, you will hear the fuel flowing sound.

2 Inspect ecm power source circuit

3 Inspect circuit opening relay

- Remove the circuit opening relay from the instrument panel j/b.

- check for continuity in the circuit opening relay.

Standard:

- Reinstall the circuit opening relay.

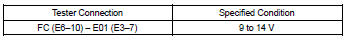

4 Inspect ecm(fc voltage)

- Turn the ignition switch on.

- measure the voltage between the terminals of the e3 and e6 ecm connectors.

Standard:

5 Check harness and connector(efi relay – circuit opening relay)

- Remove the efi relay from the engine room r/b.

- remove the circuit opening relay from the instrument panel j/b.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reinstall the circuit opening relay.

- reinstall the efi relay.

Replace ecm

6 Inspect fuel pump

7 Check harness and connector(circuit opening relay – fuel pump,fuel pump – body ground)

- Remove the circuit opening relay from the instrument panel j/b.

- disconnect the f10 fuel pump connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the fuel pump connector.

- reinstall the circuit opening relay.

Replace ecm

Other materials:

Disposal

Hint:

when scrapping vehicle equipped with an srs or disposing of a horn button assy,

always first deploy the

airbag in accordance with the procedure described below. If any abnormality

occurs in the airbag deployment,

contact the service dept. Of toyota motor sales, u.S.A., Inc.

Caution:

...

Symptom confirmation and diagnostic trouble code

Hint:

the diagnostic system in corolla has various functions. The first

function is the diagnostic trouble

code (dtc) check, in which a malfunction in the signal circuits to the ecu

is stored in code form in

the ecu memory. Another function is the input signal check, which checks if

...

Adjusting the set speed

To change the set speed, operate the lever until the desired set speed is obtained.

1 Increases the speed

2 Decreases the speed

Fine adjustment: Momentarily move the lever in the desired direction.

Large adjustment: Hold the lever in the desired direction.

The set speed will be increased or dec ...