Toyota Corolla (E120) 2002–2008 Repair Manual / Front suspension / Front suspension arm sub–assy lower no.1 Lh

Toyota Corolla (E120): Front suspension arm sub–assy lower no.1 Lh

Replacement

Hint

: components:

1. Remove front wheel

2. Disconnect front stabilizer link assy lh (lh (a/t) position)

3. Disconnect front stabilizer link assy rh (lh (a/t) position)

Hint

: remove the rh side by the same procedures as the lh side.

4. Separate front suspension arm sub–assy lower no.1 Lh

- Remove the bolt and 2 nuts, and separate the front suspension arm sub–assy lower no.1 Lh from the lower ball joint assy front lh.

5. Separate front suspension arm sub–assy lower no.1 Rh (lh (a/t) position)

Hint

: remove the rh side by the same procedures as the lh side.

6. Separate rack & pinion power steering gear assy (lh (a/t) position)

- remove the 4 bolts, separate the rack & pinion power steering gear

assy.

Notice

: loosen the bolt since the nut cannot be rotated.

- suspend the rack & pinion power steering gear assy.

7. Suspend engine assy (lh (a/t) position)

8. Separate front suspension crossmember sub–assy (lh (a/t) position)

- Remove the 3 bolts and 3 nuts, disconnect the transverse engine engine mounting insulator and engine mounting member sub–assy center from the front suspension crossmember sub–assy.

- Remove the 4 bolts.

- lower the transmission jack, remove the front suspension crossmember sub–assy.

9. Remove front suspension arm sub–assy lower no.1 Lh

- Remove the 2 bolts, nut and front suspension arm sub– assy lower no.1 Lh from the front suspension crossmember sub–assy.

10. Temporary tighten front suspension arm sub–assy lower no.1 Lh

- Install the front suspension arm sub–assy lower no. 1 Lh, temporarily tighten the 2 bolts and nut.

11. Install front suspension crossmember sub–assy (lh (a/t) position)

- lift the front suspension crossmember sub–assy up with a transmission jack.

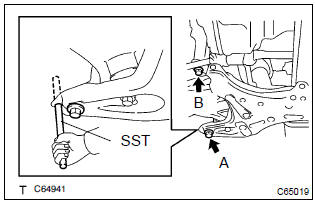

- Insert sst to the base hole of the rh side crossmember

and rh side of the vehicle.

Sst 09670–00010

- tighten the bolt temporarily in the order a and b.

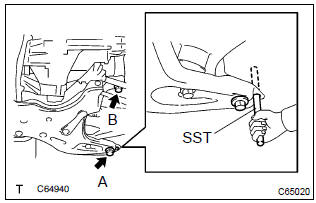

- Insert sst to the base hole of the lh side of crossmember

and lh side of the vehicle.

Sst 09670–00010

- tighten the bolt temporarily in the order a and b.

- insert sst to the base hole of the rh side of crossmember

and rh side of the vehicle.

Sst 09670–00010

- Then tighten the bolt a and b by the specified torque.

Torque:

bolt a: 157 nvm (1,601 Kgf·cm, 116 ft·lbf) bolt b: 113 nvm (1,152 Kgf·cm, 83 ft·lbf) - insert sst to the base hole of the lh side of crossmember

and lh side of the vehicle.

Sst 09670–00010

- tighten the bolt a and b by the specified torque.

Torque:

bolt a: 157 nvm (1,601 Kgf·cm, 116 ft·lbf) bolt b: 113 nvm (1,152 Kgf·cm, 83 ft·lbf)

- Connect the transverse engine engine mounting insulator and engine mounting member sub–assy center to the front suspension crossmember sub–assy.

- install the 3 bolts and 3 nuts.

Torque: 52 nvm (530 Kgf·cm, 38 ft·lbf)

12. Install rack & pinion power steering gear assy (lh (a/t) position)

- install the rack & pinion power steering gear assy with the 4

bolts.

Torque: 58 nvm (591 Kgf·cm, 43 ft·lbf)

13. Install front suspension arm sub–assy lower no.1 Lh

- Install the front suspension arm sub–assy lower no.1 Lh

with the 2 nuts and bolt to the lower ball joint assy front lh.

Torque: 89 nvm (908 Kgf·cm, 66 ft·lbf)

14. Install front suspension arm sub–assy lower no.1 Rh (lh (a/t) position)

Hint

: install the rh side by the same procedures as the lh side.

15. Install front stabilizer link assy lh (lh (a/t) position)

16. Install front stabilizer link assy rh (lh (a/t) position)

Hint

: install the rh side by the same procedure as the lh side.

17. Stabilize suspension

- install the front wheel and jack down the vehicle.

Torque: 103 nvm (1,050 Kgf·cm, 76 ft·lbf)

- bounce the vehicle up and down several times to stabilize the suspension.

18. Fully tighten front suspension arm sub–assy lower no.1 Lh

- Fully tighten the 2 bolts and nut.

Torque: 137 nvm (1,397 Kgf·cm, 101 ft·lbf)

Notice

: tighten the bolt since the nut cannot be rotated.

19. Inspect and adjust front wheel alignment

Other materials:

Meter display

■ Locations of gauges and meters

The units of measure may differ depending on the intended destination of

the vehicle.

Tachometer

Displays the engine speed in revolutions per minute

Outside temperature

Displays the outside temperature within the range of -40ºF (-40ºC) to 140ºF

(60ºC)

...

Key confinement prevention function does not work

properly (unlock warning switch circuit)

Circuit description

The unlock warning switch turns on when the key is inserted in the ignition

key cylinder and the door courtesy

switch turns on when the driver’s door is opened, and the integration relay

monitors both switches conditions.

According to these switches conditions, the int ...

Inspection procedure

1 Check hazard warning signal switch assy

Check the hazard warning switch continuity, as shown in

the illustration and table.

Standard:

2 Check turn signal flasher assy

3 Check wire harness (tvip ecu turn signal flasher)

Disconnect the tvip ecu and turn signal flashe ...