Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position sensor ”a”

circuit / Circuit description

Toyota Corolla (E120): Circuit description

The camshaft position sensor (g22+ signal) consists of a magnet, iron core and pickup coil.

The g22+ signal plate has 3 teeth on its outer circumference and is installed on the camshaft timing pulley.

When the camshafts rotate, the protrusion on the signal plate and the air gap on the pickup coil changes, causing fluctuations in the magnetic field and generating an electromotive force in the pickup coil.

The ne+ signal plate (crankshaft timing pulley) has 34 teeth and is installed to the crankshaft. The ne+ signal sensor generates 34 signals at every engine revolution. The ecm detects the crankshaft angle and the engine revolution based on the ne+ signals, and the cylinder and the angle of the vvt based on the combination of the g22+ and ne+ signals.

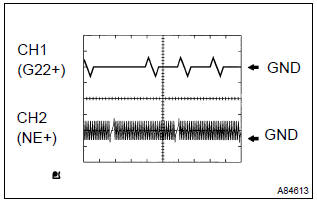

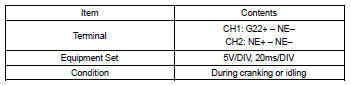

Reference: inspection using the oscilloscope.

Hint

: the correct waveform is as shown on the left.

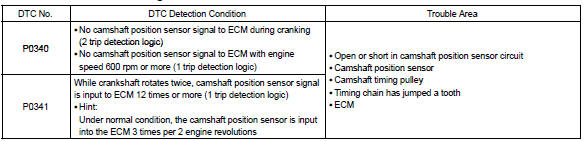

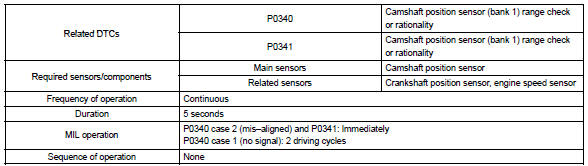

Monitor description

If there is no signal from the camshaft position sensor despite the engine revolving, or if the rotation of the camshaft and the crankshaft is not synchronized, the ecm interprets this as a malfunction of the sensor.

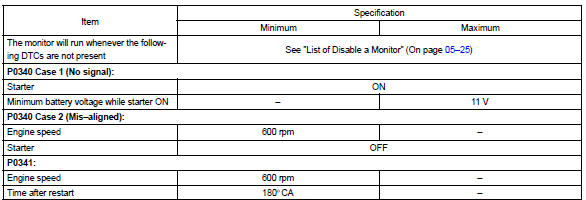

Monitor strategy

Typical enabling conditions

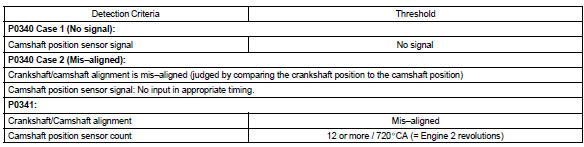

Typical malfunction thresholds

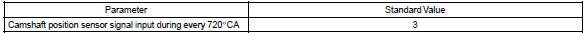

Component operating range

Wiring diagram

Refer to dtc p0335

Other materials:

Rear seats

The seatbacks of the rear

seats can be folded down.

Folding down the rear

seatbacks

1. Move the front seats forward.

2. Stow the rear armrest. (if

equipped).

3. Fold the seatback down while

pushing the seatback lock

release button.

Each seatback may be folded separately.

WARNING

Observe the follo ...

Data list/active test

1. Data list

Hint:

using the data list displayed by the hand–held tester or the obd ii scan tool,

you can read the value of

the switches, sensors, actuators and so on without parts removal. Reading the

data list as a first step

of troubleshooting is one method to shorten diagnostic time.

...

Emergency towing

If a tow truck is not available in an emergency, your vehicle may be temporarily

towed using a cable or chain secured to the emergency towing eyelet. This should

only be attempted on hard surfaced roads for short distances at low speeds.

A driver must be in the vehicle to steer and operate the ...