Toyota Corolla (E120): Overhaul

Hint

: components:

1. Remove front wheel

2. Disconnect front stabilizer link assy lh

- Remove the nut and disconnect the front stabilizer link assy lh from the shock absorber assy front lh.

Hint

: if the ball joint turns together with the nut, use a hexagon (6 mm) wrench to hold the stud.

3. Disconnect front flexible hose

- W/ abs: remove the bolt, disconnect the front flexible hose no. 1 And speed sensor front lh.

- w/o abs: remove the bolt, disconnect the front flexible hose.

4. Remove front shock absorber with coil spring

- Remove the 2 bolts and nuts on the lower side of the shock absorber assy front lh.

Notice

: when removing the bolt, stop the bolt from rotating and loosen the nut.

- Remove the 3 nuts on the upper side of the shock absorber assy front lh.

- remove the front shock absorber with the coil spring.

5. Fix front shock absorber with coil spring

- Install 2 nuts and a bolt to the bracket at the lower side of the shock absorber assy front lh and secure it in a vise.

6. Remove shock absorber assy front lh

- Remove the front suspension support dust cover lh from the front suspension support sub–assy lh.

- using sst, compress the front coil spring lh.

Sst 09727–30021

N

otice

: do not use an impact wrench. It will damage the sst.

- Using sst to hold the front coil spring seat upper lh, remove

the nut.

Sst 09729–22031

- remove the front suspension support sub–assy lh, front suspension support lh dust seal, front coil spring seat upper lh, front coil spring insulator upper lh, front coil spring lh, front spring bumper lh and front coil spring insulator lower lh.

7. Inspect shock absorber assy front lh

- Compress and extend the shock absorber rod and check that there is no abnormal resistance or unusual sound during operation.

If there is any abnormality, replace the shock absorber with a new one.

Notice

: when disposing of the shock absorber, see disposal on page 26–12.

8. Install shock absorber assy front lh

- install the front coil spring insulator lower lh onto the shock absorber assy front lh.

- install the front spring bumper lh to the shock absorber piston rod

- Using sst, compress the front coil spring lh.

Sst 09727–30021 Notice

: do not use an impact wrench. It will damage the sst.

- install the front coil spring lh to the shock absorber assy

front lh.

Hint

: fit the lower end of the front coil spring lh into the gap of the spring lower seat.

- Install the front coil spring insulator upper lh as shown in the illustration.

- Install the front coil spring seat upper lh to the shock absorber assy front lh with the mark facing the outside of the vehicle.

- install the front suspension support lh dust seal and front suspension support sub–assy lh.

- Using sst to hold the front coil spring seat upper lh,

install a new nut.

Sst 09729–22031

torque: 47 nvm (479 Kgf·cm, 35 ft·lbf) - remove the sst.

- install the front suspension support dust cover lh.

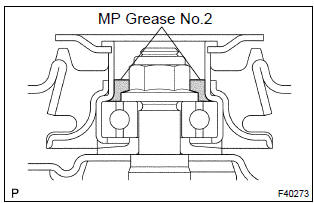

- Apply mp grease no.2 Into the suspension support sub– assy lh.

Caution

: do not touch grease on rubber surface of upper support.

9. Install front shock absorber with coil spring

- Install the shock absorber with the 2 bolts.

- install the 3 nuts to the upper side of front shock absorber

with coil spring.

Torque: 39 nvm (398 Kgf·cm, 29 ft·lbf)

- Install the 2 bolts and nuts to the lower side of front shock

absorber with coil spring.

Torque: 153 nvm (1,560 Kgf·cm, 113 ft·lbf)

N

otice

: when installing bolt, stop the bolt from rotating and torque the nut.

10. Install front flexible hose

- W/ abs:

install the front flexible hose and speed sensor front lh

with the bolt.

Torque: 29 nvm (296 Kgf·cm, 21 ft·lbf)

- w/o abs:

install the front flexible hose with the bolt.

Torque: 29 nvm (296 Kgf·cm, 21 ft·lbf)

11. Install front stabilizer link assy lh

- install the front stabilizer link assy lh with the nut.

Torque: 74 nvm (755 Kgf·cm, 55 ft·lbf)

Hint

: if the ball joint turns together with the nut, use a hexagon wrench (6 mm) to hold the stud.

12. Install front wheel torque: 103 nvm (1,050 Kgf·cm, 76 ft·lbf)

13. Inspect and adjust front wheel alignment

Other materials:

If the vehicle battery is discharged

The following procedures may be used to start the engine if the vehicle’s

battery is discharged.

You can also call your Toyota dealer or a qualified repair shop.

If you have a set of jumper (or booster) cables and a second vehicle with a 12-volt

battery, you can jump start your vehicle by fo ...

Circuit description

The side squib (lh) circuit consists of the airbag sensor assy center and

front seat airbag assy (lh).

It causes the srs to deploy when the srs deployment conditions are satisfied.

Dtc b0115/47 is recorded when a short is detected in the side squib (lh)

circuit.

Wiring diagram

...

Receiving a phone call

Answering the phone

Press the off-hook switch.

Refusing a call

Press the on-hook switch.

Receiving a call when on another call

Press the off-hook switch.

Pressing the off-hook switch again returns you to the previous call.

Adjusting the ringtone volume when receiving a call

Change the ringto ...