Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p squib circuit (to ground) / Inspection procedure

Toyota Corolla (E120): Inspection procedure

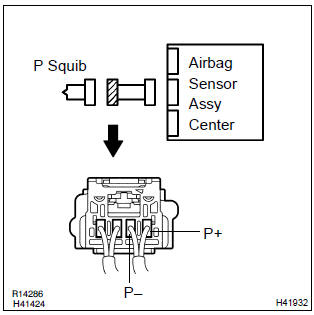

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the instrument panel passenger airbag assy.

- for the connector (on the instrument panel passenger airbag

assy side) between the airbag sensor assy center

and the instrument panel passenger airbag assy, measure

the resistance between p+ and body ground.

Ok: resistance: 1 mΩ or higher

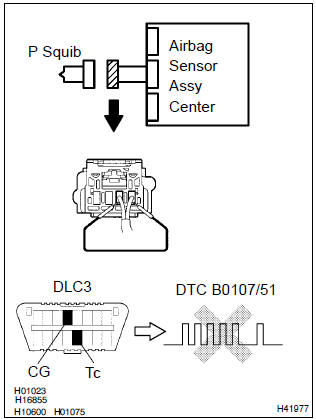

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- using a service wire, connect p+ and p– of the connector (on the instrument panel passenger airbag assy side) between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0107/51 is not output.

Hint

: codes other than code b0107/51 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0107/51 is not output.

Hint: codes other than code b0107/51 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Do-it-yourself service precautions

If you perform maintenance by yourself, be sure to follow the correct procedure

as given in these sections.

CAUTION

The engine compartment contains many mechanisms and fluids that may move suddenly,

become hot, or become electrically energized. To avoid death or serious injury,

observe t ...

Circuit description

The p/t squib (lh) circuit consists of the airbag sensor assy center and seat

belt pretensioner (lh).

It causes the srs to deploy when the srs deployment conditions are satisfied.

Dtc b0135/73 is recorded when a short is detected in the p/t squib (lh) circuit.

Wiring diagram

...

Installing the spare tire

1 Remove any dirt or foreign matter from the wheel contact surface.

If foreign matter is on the wheel contact surface, the wheel nuts may loosen

while the vehicle is in motion, causing the tire to come off.

2 Install the tire and loosely tighten each wheel nut by hand by approximately

the sa ...