Toyota Corolla (E120) 2002–2008 Repair Manual / Automatic transmission / trans / Floor shift parking lock cable assy (atm)

Toyota Corolla (E120): Floor shift parking lock cable assy (atm)

Replacement

1. Precaution

2. Disconnect battery negative terminal

3. Place front wheels facing straight ahead

4. Remove horn button assy

5. Remove steering wheel assy

sst 09950–50013 (09951–05010, 09952–05010, 09953–05020, 09954–05021)

6. Remove steering column cover

7. Remove console panel upper

8. Remove parking brake hole cover sub–assy

9. Remove console box carpet

10. Remove console box sub–assy rear

11. Remove floor shift parking lock cable assy

- Remove the cable end from the lever pin of the floor shift assembly.

- Using a screwdriver, disconnect the parking lock cable from the floor shift assembly.

- Disconnect the cable clamp.

- turn the ignition switch acc or on.

- Using a screwdriver, remove the cable from the upper bracket.

Hint

: before disconnecting the cable, keep in mind each of the physical relationship between the connector and wire harness or other cables

12. Install floor shift parking lock cable assy

- Turn the ignition switch acc or on.

- install the cable to the upper bracket.

Hint

: connect the removed cable so that it will be the same physical relationship you kept in mind before its disconnection.

- Connect the cable clamp.

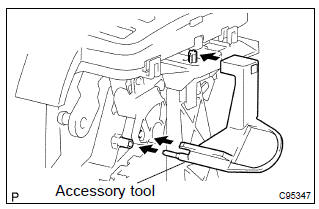

- Set the accessory tool.

- Shift the shift lever to n position and turn the ignition switch to acc or on.

- Set the accessory tool to the shift lock control unit

assy as shown in the illustration.

Accessory tool parts no.: 33693–02010

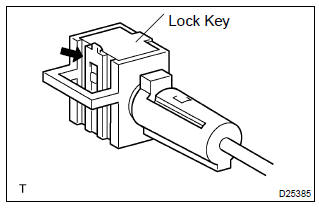

- Using a screwdriver, unlock the claw of the lock key of automatic adjustment part.

- Insert the slide cap into the through hole and install.

- Insert the lever pin into the hole in the cable end.

Hint

: fit the claws securely.

- Lock the lock key.

Hint

: at this time, the shift lever should be in n position and the ignition key should be set to acc or on.

- remove the accessory tool.

Accessory tool parts no.: 33693–02010

13. Install steering wheel assy

14. Inspect steering wheel center point

15. Install horn button assy

16. Inspect srs warning light

17. Check key interlock operation

Other materials:

Tire pressure warning system (if equipped)

Your vehicle is equipped with a tire pressure warning system that uses tire pressure

warning valves and transmitters to detect low tire inflation pressure before serious

problems arise.

◆ Installing tire pressure warning valves and transmitters

When replacing tires or wheels, tire press ...

Installing child restraints

Follow the child restraint system manufacturer's instructions.

Firmly secure child restraints to the seats using the LATCH anchors or a seat

belt. Attach the top tether strap when installing a child restraint.

The lap/shoulder belt can be used if your child restraint system is not compatible ...

Circuit description

The intake air temperature (iat) sensor, mounted on the mass

air flow (maf) sensor, monitors the intake air temperature. The

iat sensor has a thermistor that varies its resistance depending

on the temperature of the intake air. When the air temperature

is low, the resistance in the thermisto ...