Toyota Corolla (E120) 2002–2008 Repair Manual / Introduction / Repair instruction / Precaution / Basic repair hint

Toyota Corolla (E120): Basic repair hint

(A) hints on operations

| 1 | Looks |

|

| 2 | Vehicle protection |

|

| 3 | Safe operation |

|

| 4 | Preparation of tools and measuring gauge |

|

| 5 | Removal and installation, disassembly and assembly operations |

|

| 6 | Removed parts |

|

(B) jacking up and supporting vehicle

- Care must be taken when jacking up and supporting the vehicle. Be sure to lift and support the vehicle at the proper locations

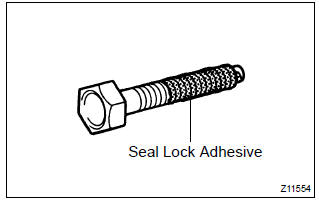

(C) precoated parts

- Precoated parts are bolts, nuts, etc. That are coated with a seal lock adhesive at the factory.

- If a precoated part is retightened, loosened or caused to move in any way, it must be recoated with the specified adhesive.

- When reusing precoated parts, clean off the old

adhesive and dry the part with compressed air.

Then apply the specified seal lock adhesive to the bolt, nut or threads.

Notice

: perform the torque checking with the lower limit value of the torque tolerance.

- Depending on the seal lock agent to apply, there may be a case where it is necessary to leave it for a specified time until it hardens.

- Gaskets

(1) when necessary, use a sealer on gaskets to prevent leaks. - bolts, nuts and screws (1) carefully observe all the specifications for tightening torques. Always use a torque wrench.

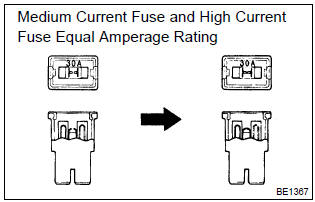

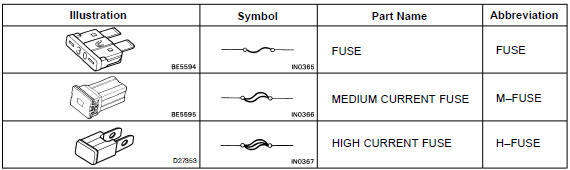

- fuses.

(1) When replacing fuses, be sure that a new fuse has the correct amperage rating. Do not exceed the rating, or use one with a lower rating.

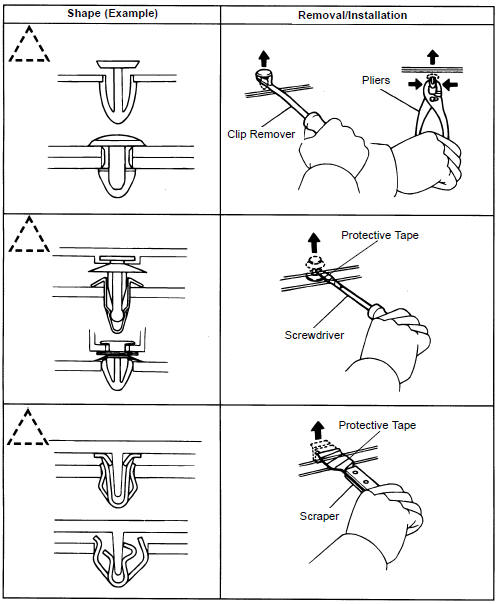

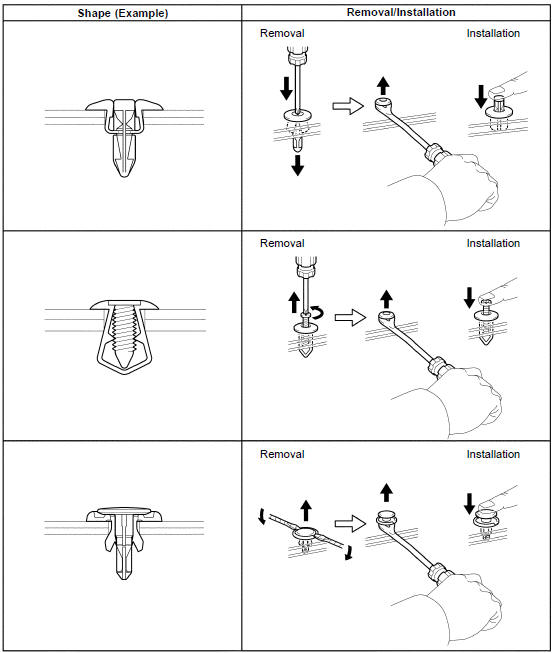

- Clips

(1) the removal and installation methods of typical clips used in body parts are shown in the table below.

Hint

: if the clip is damaged during the a procedure, always replace it with a new clip.

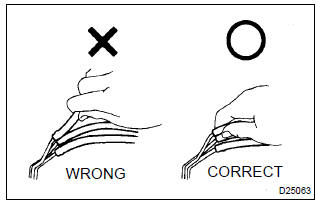

- Removal and installation of vacuum hoses (1) to disconnect vacuum hoses, pull them by holding the end, not the middle of the hose.

(2) When disconnecting vacuum hoses, use tags to identify where they should be reconnected.

(3) After completing the job, make a double check whether the vacuum hoses are properly connected.

A label under the hood shows the proper layout.

(4) When using a vacuum gauge, never force the hose onto a connector that is too large. Use a step–down adapter for adjustment. Once the hose has been stretched, it may leak air.

- Torque when using torque wrench with extension tool

(1) in case of tightening with a torque wrench which has

an extended length by combining the torque

wrench with sst or extension tool, if you tighten until

the reading of the torque wrench reaches the

specified torque value, the actual torque becomes

excessive.

(2) In this manual, only the specified torque is described.

In case of using sst or an extension tool, calculate the reading of the torque wrench by the following formula.

(3) Formula t’=t x l2/(l1 + l2)

| T’ | Reading of torque wrench {nvm (kgf·cm, ftvlbf)} |

| T | Torque {nvm (kgf·cm, ftvlbf)} |

| L1 | Length of sst or extension tool (cm) |

| L2 | Length of torque wrench (cm) |

Other materials:

Inspection procedure

Hint:

if dtcs p0115, p0116, p0117, p0118 and p0125 are output

simultaneously, the engine coolant temperature

sensor circuit may be open or short. Perform the troubleshooting of dtc

p0115, p0117 or

p0118 first.

Read freeze frame data using the hand-held tester or the obd ii scan

to ...

Removal & installation and disassembly & re

1. Remove bench type rear seat cushion assy (, 72–8)

2. Remove rear floor service hole cover

3. Work for preventing gasoline from spilling out

start the engine.

after the engine has stopped on the its own, turn the ignition

switch to lock.

4. Disconnect fuel tank main tu ...

Starting & charging

Preparation

Sst

Recomended tools

Equipment

...