Toyota Corolla (E120): System description

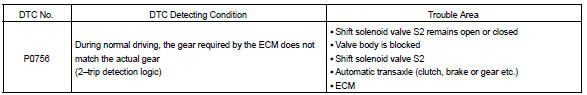

The ecm uses signals from the vehicle speed sensor and crankshaft position sensor to detect the actual gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual gear with the shift schedule in the ecm memory to detect the mechanical trouble of the shift solenoid valves, the valve body or automatic transaxle (clutch, brake or gear etc.).

Monitor description

The ecm commands gear shifts by turning the shift solenoid valves ”on/off”. According to the input shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ecm detects the actual gear position (1st, 2nd, 3rd or o/d gear position). When the gear position commanded by the ecm and the actual gear position are not same, the ecm illuminates the mil.

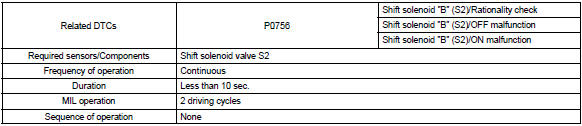

Monitor strategy

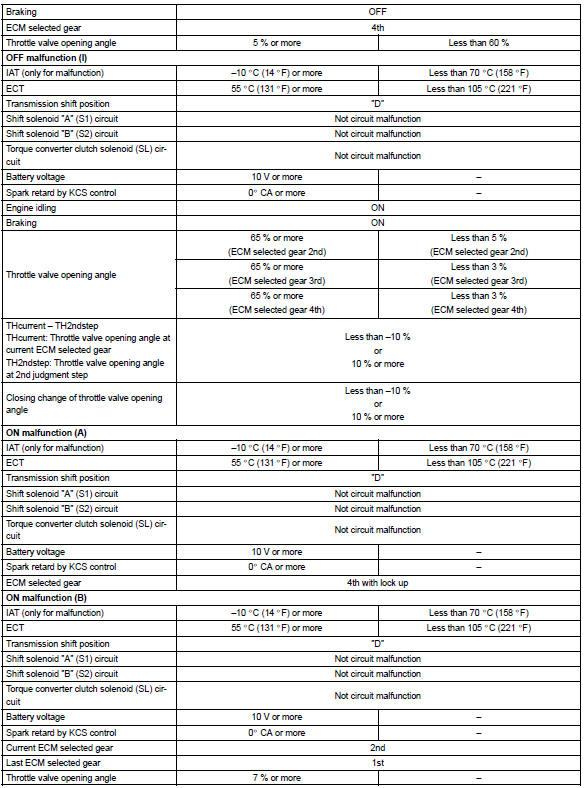

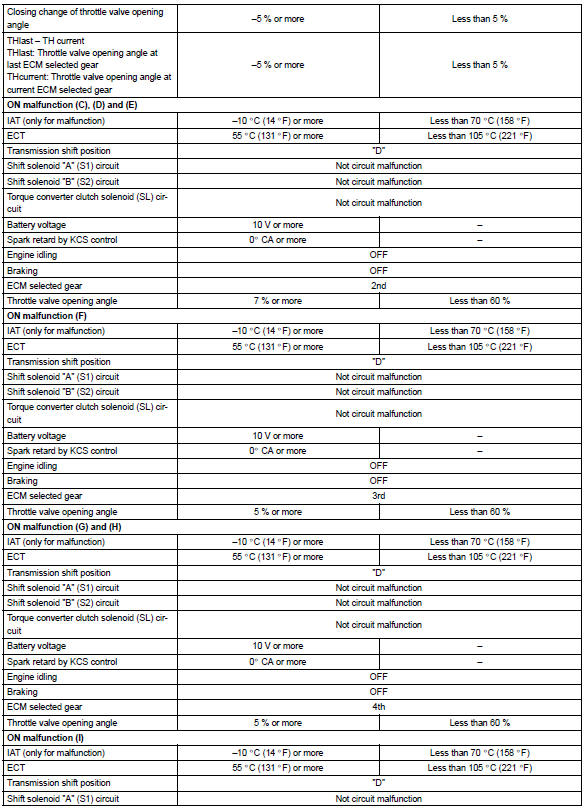

Typical enabling conditions

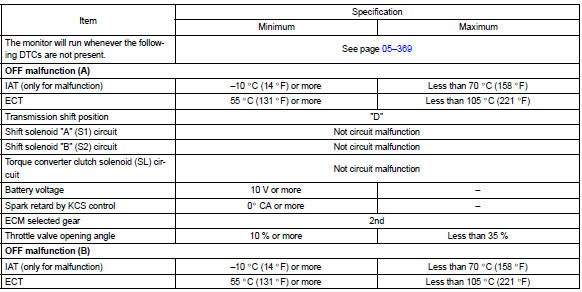

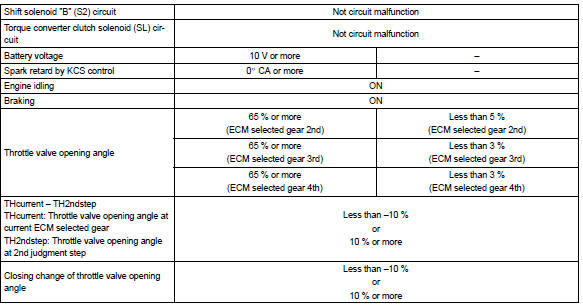

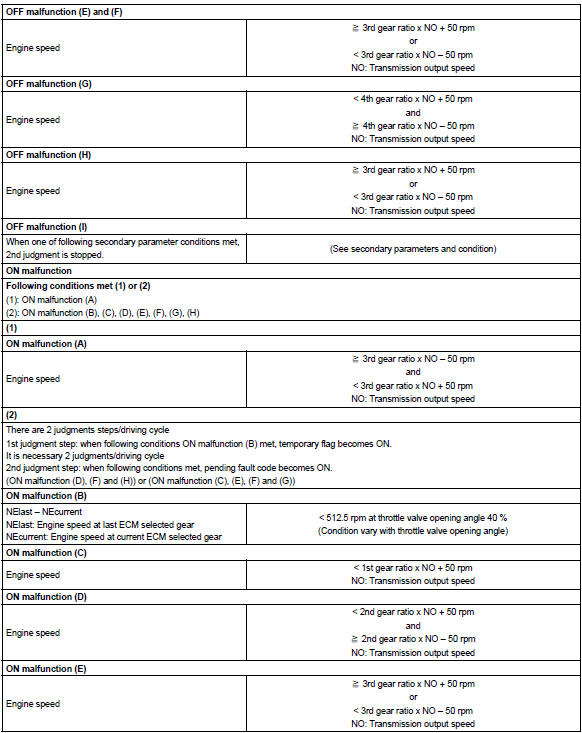

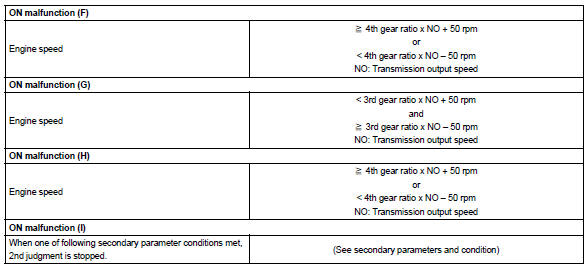

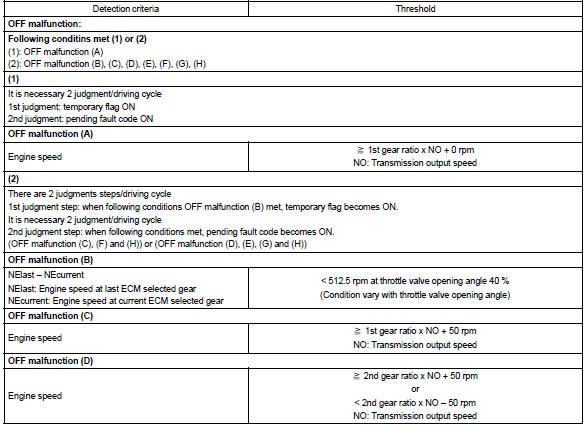

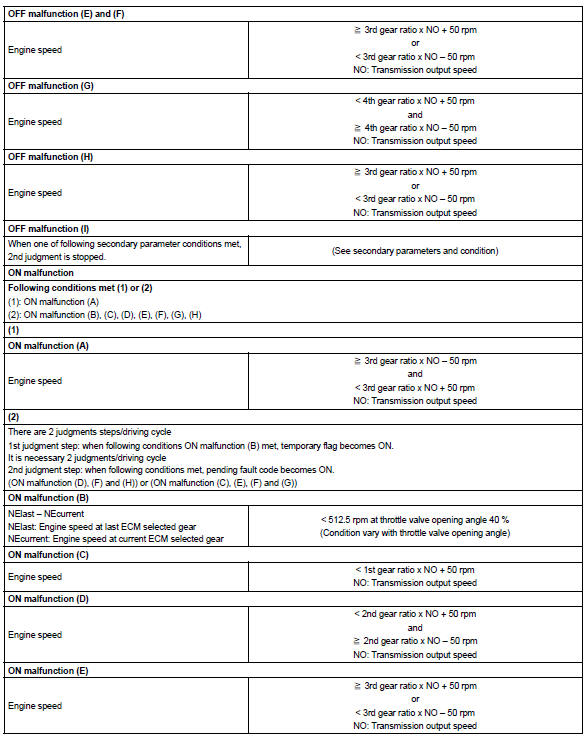

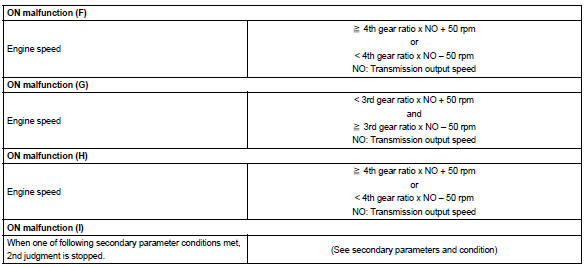

Typical malfunction thresholds

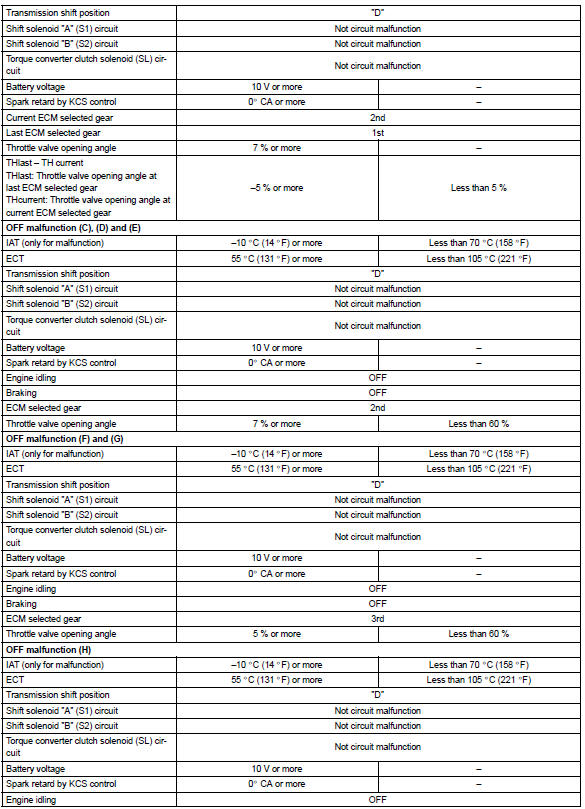

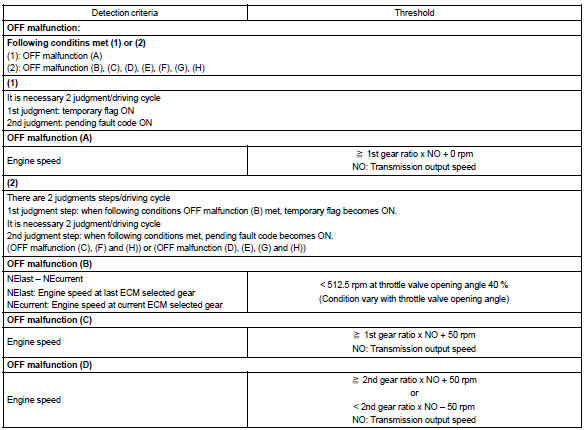

Typical malfunction thresholds

Other materials:

Radio receiver assy

Replacement

Рint: components:

1. Remove floor shift shift lever knob sub–assy (m/t transaxle)

2. Remove console panel upper

3. Remove heater control knob

4. Remove instrument cluster finish panel

5. Remove instrument cluster finish panel sub–assy

center

Remove the 4 screws.

& ...

Overhaul

1. Remove manual transaxle assy

2. Remove clutch release fork sub–assy

Remove the clutch release fork with clutch release bearing

from the transaxle assy.

3. Remove clutch release bearing assy

remove the clutch release bearing assy from the clutch

release fork.

4. Re ...

Overhaul

1. Remove console panel upper

2. Remove console box carpet

3. Remove parking brake hole cover sub–assy

4. Remove console box sub–assy rear

5. Disconnect floor shift cable transmission control shift

Remove the cable end from the rod of the floor shift assembly.

Using a s ...