Toyota Corolla (E120) 2002–2008 Repair Manual / Heater & air conditioner / Refrigerant / On–vehicle inspection

Toyota Corolla (E120): On–vehicle inspection

1. Inspect refrigerant pressure with manifold gauge set

- this is a method in witch the trouble is located by using

a manifold gauge set. Read the manifold gauge pressure

when the these conditions are established.

Test conditions:

- temperature at the air inlet with the switch set at recirc is 30 – 35 °c (86 – 95 °f)

- engine running at 1500 rpm

- blower speed control switch at ”hi” position

- temperature control dial at ”cool” position a/c switch on

- fully open doors

- Normally functioning refrigeration system.

Gauge reading:

low pressure side:

0.15 – 0.25 Mpa (1.5 – 2.5 Kgf/cm2) high pressure side:

1.37 – 1.57 Mpa (14 – 16 kgf/cm2)

- Moisture present in refrigeration system.

|

Symptom |

Probable cause |

Diagnosis |

Remedy |

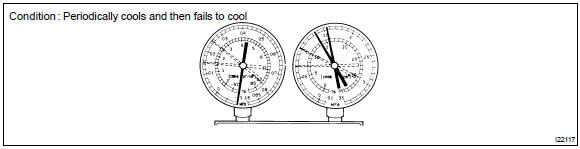

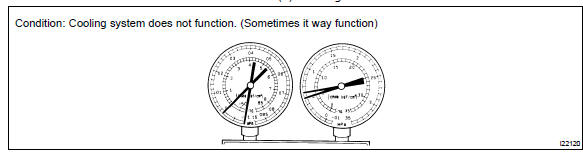

| During operation, pressure on low pressure side sometimes become a vacuum and sometime normal | Moisture in refrigerating system freezes at expansion valve orifice causing a temporary stop of cycle, however, when it melts, normal state is restored. |

|

|

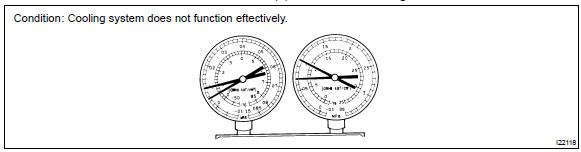

- Insufficient cooling

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

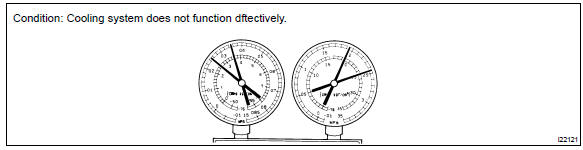

Gas leakage in refrigeration system |

|

|

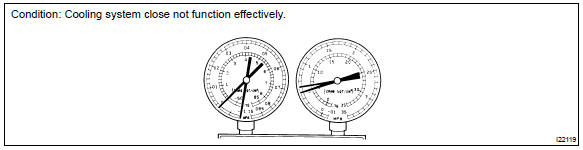

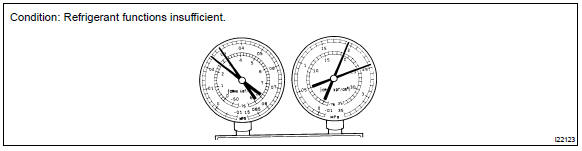

- Poor circulation of refrigerant

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Refrigerant flow obstructed by dirt in receiver | Receiver clogged | Replace condenser |

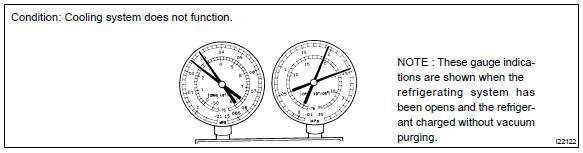

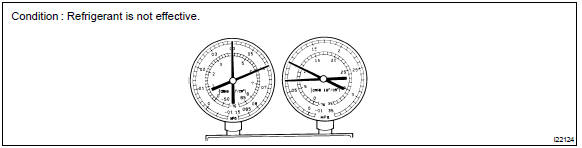

- Refrigerant does not circulate

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

|

Refrigerant does not circulate |

|

- Refrigerant overcharged or insufficient cooling of condenser

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

|

|

|

- Air present in refrigeration system

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Air entered in refrigerating system |

|

|

- Expansion valve improperly

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Trouble in expansion valve |

|

Check expansion valve |

- Defective compression compressor

|

Symptom |

Probable cause |

Diagnosis |

Corrective actions |

|

Internal leak in compressor |

|

Repair or replace compressor |

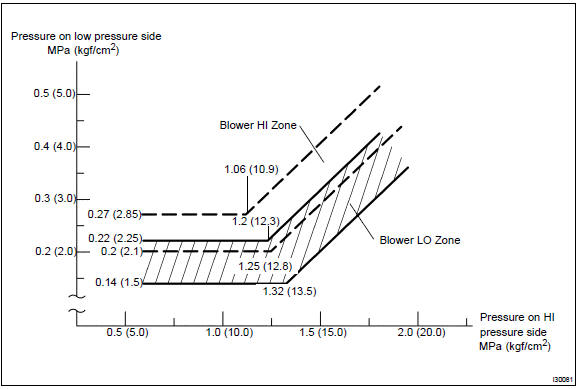

Gauge readings (reference)

Other materials:

Replacement

1. Drain brake fluid

Notice:

wash the brake fluid off immediately if it comes into contact with any painted

surface.

2. Remove front wheel rh

3. Remove front fender liner rh

4. Remove brake actuator with bracket

turn the latch of the actuator connector to disconnect the

connector. ...

Rear seats

The seatbacks of the rear seats can be folded down.

The seatbacks of the rear seats can be folded down.

1 Stow the rear outside seat belt buckles and stow the rear center seat belt

buckle as shown.

2 Pull the seatback lock release knob and fold the seatback down.

CAUTION

■When foldi ...

Check mode procedure

Hint:

hand–held tester only:

compared to the normal mode, the check mode has more sensing

ability to detect malfunctions. Furthermore, the same diagnostic

items which are detected in the normal mode can also be

detected in the check mode.

1. Check mode procedure(using the hand–held tester) ...