Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Combination meter / Malfunction in tachometer

Toyota Corolla (E120): Malfunction in tachometer

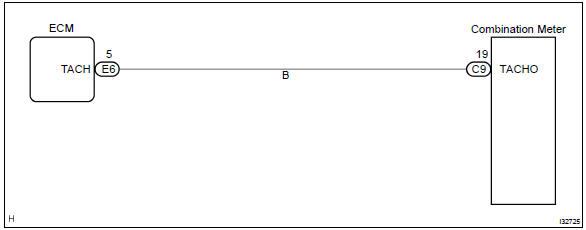

Wiring diagram

Inspection procedure

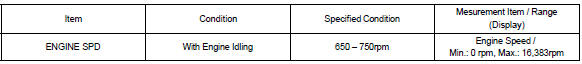

- Check output value of ecm.

- Connect the hand–held tester to dlc3.

- Turn the ignition switch to on and push the hand–held tester main switch on.

- Select the data list mode on the hand–held tester.

2 Inspect combination meter assy

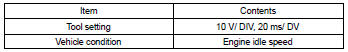

(Reference) inspection using oscilloscope

- check the input signal waveform.

- Remove the combination meter assy with connectors still connected.

- Connect the oscilloscope to the terminals c9–19 of combination meter assy and body ground.

- Start engine.

- Check the signal waveform.

3 Check harness and connector(between ecm and combination meter assy)

- Remove the combination meter.

- check the continuity between terminals 5 (tach) of ecm and c9–19 of combination meter connector.

Standard: there is continuity.

Check and replace ecm

Other materials:

Circuit description

In the diagram below, when the engine is cranked, current flows from terminal

st2 of the ignition switch to

the starter relay coil and also current flows to terminal sta of the ecm (sta

signal).

When the sta signal and ne signal are input to the ecm, tr is turned on, current

flows to the c ...

On–vehicle inspection

1. Connect hand–held tester:

connect the hand–held tester to the dlc3.

start the engine and run it at idle.

select the active test mode on the hand–held tester.

Hint:

please refer to the hand–held tester operator’s manual for further details.

2. Inspect actua ...

Overhaul

1. Remove oil filler cap sub–assy

Remove the oil filler cap from the cylinder head cover.

2. Remove oil filler cap gasket

Using a screwdriver, remove the gasket from the oil filler

cap.

3. Remove ventilation valve sub–assy

Remove the ventilation valve from the cyl ...