Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in d squib (2nd step) circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

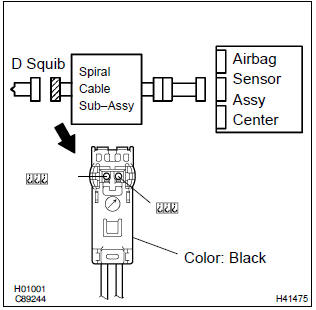

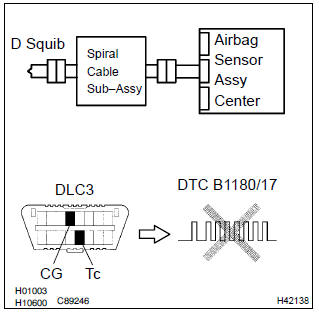

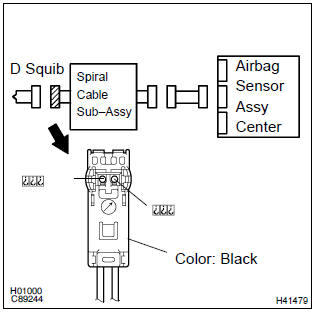

1 Check d squib circuit(airbag sensor assy center – horn button assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the horn button assy.

- release the airbag activation prevention mechanism of the connector (on the airbag sensor assy center side) between the airbag sensor assy center and the spiral cable sub–assy .

- for the black connector (on the spiral cable sub–assy

side ) between the horn button assy and the spiral cable

sub–assy, measure the resistance between d2+ and

d2–.

Ok: resistance: 1 mw or higher

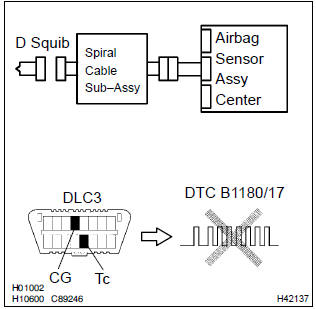

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1180/17 is not output.

Hint

: codes other than code b1180/17 may be output at this time, but they are not relevant to this check.

3 Check d squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the horn button assy connectors.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1180/17 is not output.

Hint

: codes other than code b1180/17 may be output at this time, but they are not relevant to this check.

Use simulation method to check

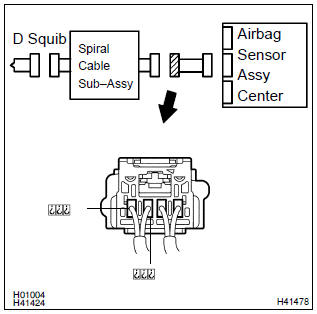

4 Check instrument panel wire(airbag sensor assy center – spiral cable sub–assy)

- Disconnect the connector of the instrument panel wire.

- release the airbag activation prevention mechanism of the connector (on the airbag sensor assy center side) between the airbag sensor assy center and the spiral cable sub–assy .

- for the connector (on the spiral cable sub–assy side) between

the airbag sensor assy center and the spiral cable

sub–assy, measure the resistance between d2+ and

d2–.

Ok: resistance: 1 mw or higher

5 Check spiral cable sub–assy

- Release the airbag activation prevention mechanism of the spiral cable sub–assy connector on the airbag sensor assy center side .

- for the black connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the resistance between d2+ and

d2–.

Ok: resistance: 1 mw or higher

Use simulation method to check

Other materials:

Content of driving information

■ Display items

Speedometer display/Driving

range

Fuel economy

Eco Driving Indicator/Driving

range

■ Speedometer display/Driving

range

Speedometer display

Driving range

Displays driving range with remaining

fuel. Use the displayed values

as a reference only.

This distance is computed ...

On–vehicle inspection

1. Inspect w/receiver condenser assy

if a fin of the w/receiver condenser assy is dirty, clean it with

water and dry it with compressor air.

Notice:

do not damage the fin of the w/receiver condenser assy.

if a fin of the w/receiver condenser assy is bent, make it

straig ...

Rear seats

► Type A

1 Up

Pull the head restraints up.

2 Down

Push the head restraint down while pressing the lock release button.

► Type B

1 Up

Pull the head restraints up.

2 Down

Push the head restraint down while pressing the lock release button.

■Removing the head restraints ...