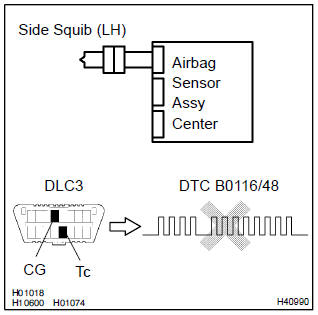

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Open in side squib (lh) circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

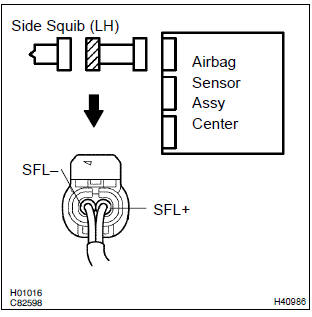

1 Check side squib(lh) circuit(airbag sensor assy center – front seat airbag assy lh)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the front seat airbag assy (lh).

- for the connector (on the front seat airbag assy side) between

the airbag sensor assy center and the front seat

airbag assy (lh), measure the resistance between sfl+

and sfl–.

Ok: resistance: below 1 Ω

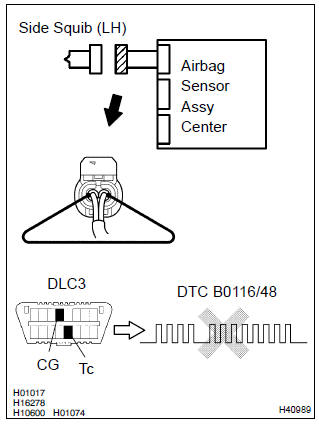

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- using a service wire, connect sfl+ and sfl– of the connector (on the front seat airbag assy side) between the airbag sensor assy center and the front seat airbag assy (lh).

- connect the negative (–) terminal cable to the battery, and wait at least 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0116/48 is not output.

Hint

: codes other than code b0116/48 may be output at this time, but they are not relevant to this check.

3 Check side squib(lh)

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the front seat airbag assy (lh) connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0116/48 is not output.

Hint

: codes other than code b0116/48 may be output at this time, but they are not relevant to this check.

Use simulation method to check

Other materials:

Inspection procedure

1 Check courtesy lamp switch

Check the courtesy switch, as shown in the illustration

and table.

Standard:

2 Check wire harness (integration relay door courtesy sw)

Disconnect the integration relay and door courtesy connectors.

check the continuity between th ...

Adding a new phone number

Select “Add contacts” using . ●

Transferring all contacts from the cellular phone

Select “Overwrite all contacts” using

and press

(YES).

● Transferring one contact from the cellular phone

Select “Add one contact” using and

press (YES). ...

Inspection procedure

1 Check harness and connector(transmission control switch –

body ground)

Disconnect the transmission control switch connector of

shift lever assy.

measure the resistance according to the value(s) in the

table below.

Standard:

2 Inspect transmission control switch

M ...