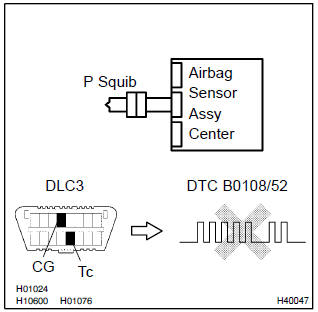

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p squib circuit (to b+) / Inspection procedure

Toyota Corolla (E120): Inspection procedure

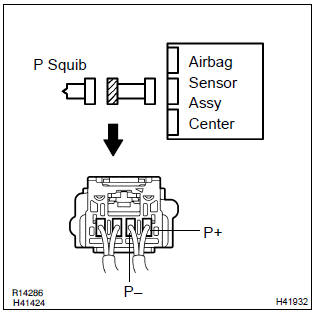

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

- for the connector (on the instrument panel passenger airbag

assy side) between the airbag sensor assy center

and the instrument panel passenger airbag assy, measure

the voltage between p+ and body ground.

Ok: voltage: below 1 v

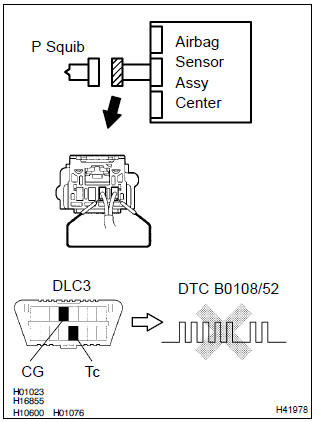

2 Check air bag sensor assy center

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the connector to the airbag sensor assy center.

- using a service wire, connect p+ and p– of the connector (on the instrument panel passenger airbag assy side) between the airbag sensor assy center and the instrument panel passenger airbag assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0108/52 is not output.

Hint

: codes other than code b0108/52 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0108/52 is not output.

Hint

: codes other than code b0108/52 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Inspection procedure

1 Input signal check

See input signal check on page 05–745.

check indicator light operation when driving with vehicle

speed above 40 km/h (25 mph), and with vehicle speed

below 40 km/h (25 mph).

Ok:

vehicle speed above 40 km/h (25 mph):

indicator light blinks

vehicle speed be ...

How to proceed with troubleshooting

1 Vehicle brought to workshop

2 Customer problem analysis

3 Check and clear dtc

4 Problem symptom confirmation

Symptom does not occur (go to

step 5)

5 Symptom simulation

6 Dtc check

7 Dtc chart

8 Problem symptoms table

9 Circuit inspection

10 Confirmation test

End

...

Sound quality is bad in all modes (volume is too low)

Wiring diagram

Inspection procedure

1 Adjust sound quality

Adjust the sound quality.

Operate the radio receiver assy to adjust the sound quality.

Standard: malfunction disappear.

2 Compare it with another car of same model

Compare it with another vehicle of the same mo ...