Toyota Corolla (E120): Inspection procedure

Hint

: start the inspection from step 1 in case of using the hand–held tester and start from step 2 in case of not using hand–held tester.

1 Inspect brake actuator assy

- Select the datalist mode on the hand–held tester.

- check the operation sound of the abs pump motor when operating it

with the hand–held tester.

Ok: the operation sound of the abs pump motor should be heard.

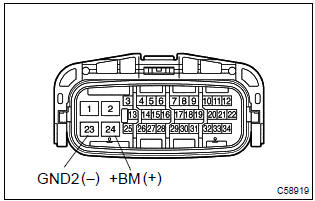

2 Inspect skid control ecu terminal voltage(+bm terminal voltage)

- Disconnect the skid control ecu connector.

- measure the voltage between terminal +bm (24) and

gnd (23) of skid control ecu harness side connector.

Ok: the operation sound of the abs pump motor should be heard.

Replace brake actuator assy

Other materials:

Overhaul

1. Remove generator pulley

Sst 09820–63010 (09820–06010, 09820–06020)

Hint:

Hold sst 1 – a with a torque wrench, and tighten sst 1

– b clockwise to the specified torque.

Torque: 39 nvm (398 Kgf·cm, 29 ft·lbf)

Notice:

check that sst is secured to the rotor shaft.

...

How to proceed with troubleshooting

Hint:

troubleshooting of the wireless door lock control system is based on

the premise that the power door

lock system is operating normally. Therefore, before troubleshooting the

wireless door lock control system,

first make certain that the the power door lock system is operating

...

Overhaul

1. Remove console panel upper

2. Remove console box carpet

3. Remove parking brake hole cover sub–assy

4. Remove console box sub–assy rear

5. Disconnect floor shift cable transmission control shift

Remove the cable end from the rod of the floor shift assembly.

Using a s ...