Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / ABS with EBD system / Right/Left front speed sensor circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: start the inspection from step 1 in case of using the hand–held tester and start from step 2 in case of not using the hand–held tester.

1 Read value of hand–held tester(front speed sensor)

- Select the datalist mode on the hand–held tester.

- check that there is no difference between the speed value output

from the speed sensor displayed

by the hand–held tester and the speed value displayed by the speedometer

when driving the vehicle.

Ok: there is almost no difference in the displayed speed value.

Hint

: there is tolerance of 10 % in the speedometer indication.

2 Inspect front speed sensor

- Remove the fender liner.

- disconnect the speed sensor connector.

- measure resistance between terminals 1 and 2 of the

speed sensor connector.

Ok: 0.6 – 2.5 Kw or 0.9 – 1.8 Kw at 20 c

- measure resistance between each of terminals 1 and 2 of

speed sensor connector and body ground.

Ok: resistance: 1 mw or higher

Notice

: check the speed sensor signal last

3 Check harness and connector(front speed sensor – skid control ecu)

- Check for open and short circuit in harness and connector between each front speed sensor and skid control ecu

4 Inspect speed sensor and sensor rotor serrations

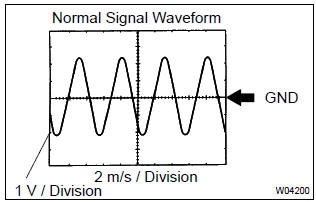

(Reference) inspection using oscilloscope

- connect the oscilloscope to the terminal fr+ – fr– and fl+ – fl– of the skid control ecu.

- drive the vehicle at about 30 km/h (19 mph), and check the signal waveform.

Hint

:

- as the vehicle speed (wheel revolution speed) increases, a cycle of the waveform becomes shorter and the fluctuation in the output voltage becomes greater.

- When noise is identified in the waveform on the oscilloscope, error signals are generated due to the speed sensor rotor’s scratches, looseness or foreign matter deposited on it.

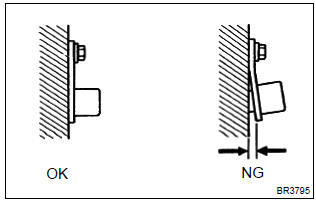

5 Inspect front speed sensor installation

- Check the speed sensor installation.

Ok: the installation bolt is tightened properly and there is no clearance between the sensor and front steering knuckle.

Torque: 8.0 Nvm (82 kgf·cm, 71 in.Vlbf)

Notice

: check the speed sensor signal last

6 Inspect speed sensor tip

- Remove the front speed sensor .

- check the sensor tip.

Ok: no scratches or foreign objects on the sensor tip.

Notice

: check the speed sensor signal last

7 Inspect speed sensor rotor

- Remove the front speed sensor rotor .

- check the sensor rotor serrations.

Ok: no scratches, missing teeth or foreign objects.

Hint

: if foreign matter is attached, remove it and after reassembling, check the output waveform.

Notice

: check the speed sensor signal last

Check and replace brake actuator assy

Other materials:

Using the radio (Multimedia system)

Radio operation

Select “AM” or “FM” on the audio source selection screen to begin listening

to the radio.

Audio control screen

Pressing the “AUDIO” button displays the audio control screen from any screens

of the selected source.

1 Audio source selection screen appears

2 Preset ...

Driving tips

Winter driving tips

Carry out the necessary preparations and inspections before driving the vehicle

in winter. Always drive the vehicle in a manner appropriate to the prevailing weather

conditions.

Preparation for winter

● Use fluids that are appropriate to the prevailing outside temper ...

Circuit description

Refer to dtc p0120

Dtc no.

Dtc detection condition

Trouble area

P0121

The following condition is met 4 times. After the vehicle speed

has exceeded 19 mph (30 km/h) once, the throttle position

sensor output value is out of normal range when the throttle

...