Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Idle air control System/ Circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

:

- when the throttle position is slightly opened (the accelerator pedal is slightly depressed) because a floor carpet is overlapped on the accelerator pedal, or if not fully releasing the accelerator pedal, etc., Dtc p505 will possibly be detected.

- Read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

Hand–held tester:

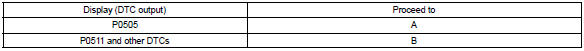

1 Check other dtc output

- Connect the hand–held tester to the dlc3.

- turn the ignition switch on and push the hand–held tester main switch on.

- read the dtcs.

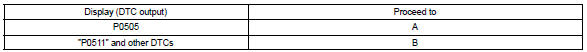

Result:

2 Check connection of pcv hose

3 Check air induction system

4 Perform active test using hand–held tester(check iac valve operation)

- Warm up the engine to the normal operating temperature.

- switch off all the accessories.

- switch off the a/c.

- shift the lever into the neutral position.

- connect the hand–held tester to the dlc3.

- select the item ”diagnosis / enhanced obd ii / active test / isc duty ratio”.

- check that the engine rpm varies when changing the isc duty ratio.

Engine rpm: engine rpm fluctuates up and down in response to the isc duty ratio variation.

5 Check a/c signal circuit

6 Check blockage of iac valve and passage to bypass throttle valve

7 Check harness and connector

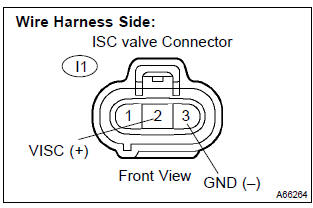

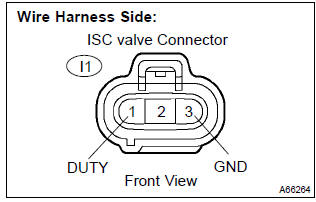

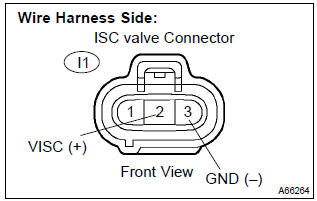

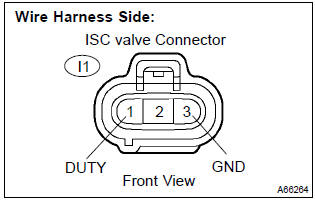

- Disconnect the i1 iac valve connector.

- turn the ignition switch on.

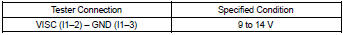

- measure the voltage between the terminals of the iac valve wire harness side connector.

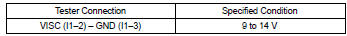

Standard:

- Reconnect the iac valve connector.

8 Check harness and connector(iac valve – ecm)

- Disconnect the i1 iac valve connector.

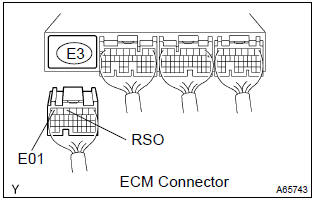

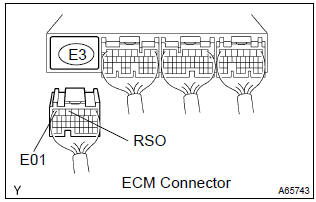

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

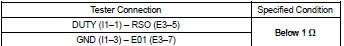

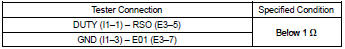

Standard (check for open):

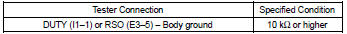

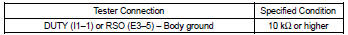

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the iac valve connector.

9 Inspect idle air control valve

Replace ecm

Obd ii scan tool (excluding hand–held tester):

1 Check other dtc output

- Connect the hand–held tester to the dlc3.

Result:

2 Check connection of pcv hose

3 Check air induction system

4 Check a/c signal circuit

5 Check blockage of iac valve and passage to bypass throttle valve

6 Check harness and connector

- Disconnect the i1 iac valve connector.

- turn the ignition switch on.

- measure the voltage between the terminals of the iac valve wire harness side connector.

Standard:

- Reconnect the iac valve connector.

7 Check harness and connector(iac valve – ecm)

- Disconnect the i1 iac valve connector.

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the iac valve connector.

8 Inspect idle air control valve

Replace ecm

Other materials:

Disposal

Hint:

when scrapping vehicle equipped with an srs or disposing of a horn button assy,

always first deploy the

airbag in accordance with the procedure described below. If any abnormality

occurs in the airbag deployment,

contact the service dept. Of toyota motor sales, u.S.A., Inc.

Caution:

...

Checking the messages

1 Display the “Message Inbox” screen.

2 Select the desired message from the list.

3 Check that the message is displayed.

1 E-mails: Select “Mark Unread” or “Mark Read” to mark mail unread or read on

the message inbox screen.

This function is available when “Update Message Read S ...

Replacement

Hint: components:

1. Precaution

2. Disconnect battery negative terminal

3. Remove instrument panel sub–assy lower

Remove the screw from the glove compartment door

stopper sub–assy.

pull the instrument panel sub–assy lower to remove it.

4. Separate passenger airbag co ...