Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position ”a” actuator

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: read freeze frame data using the hand–held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

Hand–held tester

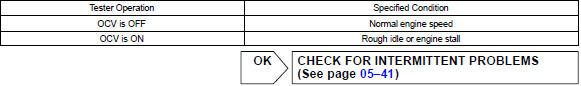

1 Perform active test by hand–held tester(operate ocv)

- Connect the hand–held tester to the dlc3.

- start the engine and warm it up.

- turn the ignition switch on and push the hand–held tester main switch on.

- select the item ”diagnosis / enhanced obd ii / active test / vvt ctrl b1”.

- check the engine speed when operating the oil control valve (ocv) by the hand–held tester.

Standard:

2 Inspect camshaft timing oil control valve assy(ocv)

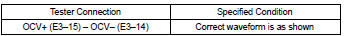

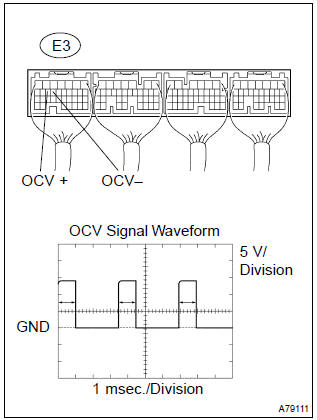

3 Inspect ecm(ocv signal)

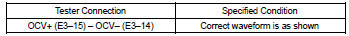

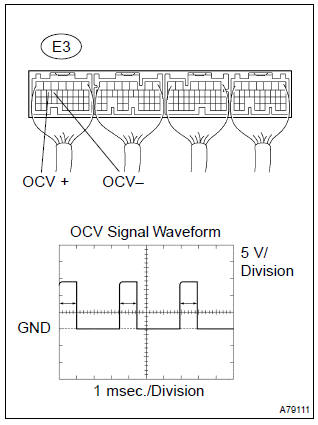

- Inspection using the oscilloscope.

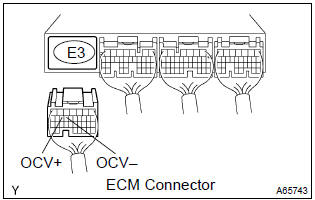

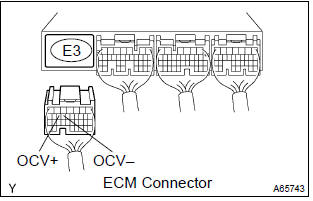

- during idling, check the waveform between the terminals of the e3 ecm connector.

Standard:

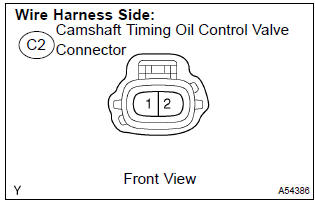

4 Check harness and connector(camshaft timing oil control valve (ocv) – ecm)

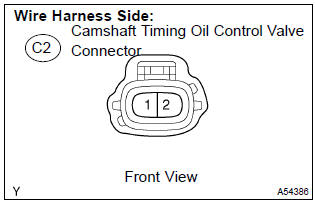

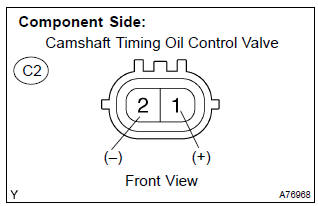

- Disconnect the c2 camshaft timing oil control valve connector.

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

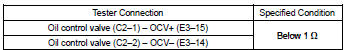

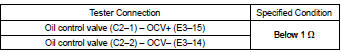

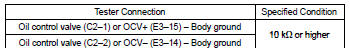

Standard (check for open):

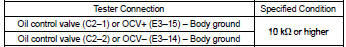

Standard (check for short):

- Reconnect the camshaft timing oil control valve connector.

- reconnect the ecm connector.

Check for intermittent problems

Obdii scan tool (excluding hand–held tester):

1 Inspect camshaft timing oil control valve assy(operate ocv)

- Disconnect the c2 camshaft timing oil control valve connector.

- apply positive battery voltage between the terminals of the camshaft timing oil control valve.

- check the engine speed.

Standard

: engine speed is rough idle or engine is stalled.

- reconnect the camshaft timing oil control valve connector.

2 Inspect ecm(ocv signal)

- Inspection using the oscilloscope.

- during idling, check the waveform between the terminals of the e3 ecm connector.

Standard:

3 Check harness and connector(camshaft timing oil control valve (ocv) – ecm)

- Disconnect the c2 camshaft timing oil control valve connector.

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the camshaft timing oil control valve connector.

- reconnect the ecm connector.

Check for intermittent problems

Other materials:

Content of driving information

■ Display items

Fuel economy

Eco Driving Indicator/Driving

range

■ Fuel economy

Use the displayed values as a reference

only.

Current fuel consumption

Displays instantaneous current fuel

consumption.

Average fuel economy (after

reset)

To reset the average fuel economy

display, press ...

Continuously variable transmission

(vehicles without paddle

shift switches)

Select the shift position

depending on your purpose

and situation.

Shift position purpose

and functions

P - Parking the vehicle/

starting the engine

R - Reversing

N - Neutral

(Condition in which the

power is not transmitted)

D - Normal driving*

B - Applying moderate

engine braking driving

down hills ...

Deleting a registered phone number

1 Select “Delete contacts” using .

2 Select the desired phone number using

and press

(YES).

To delete all of the registered phone numbers, select “All delete” using

and press

(YES). ...