Toyota Corolla (E120) 2002–2008 Repair Manual / Emission control / Engine rear oil seal

Toyota Corolla (E120): Engine rear oil seal

Replacement

1. Remove manual transaxle assy (m/t transaxle)

2. Remove automatic transaxle assy (a/t transaxle)

3. Remove clutch cover assy (m/t transaxle)

- remove the 6 bolts and clutch cover.

4. Remove clutch disc assy (m/t transaxle)

5. Remove flywheel sub–assy (m/t transaxle)

- Fix the crankshaft with sst, then remove the 8 bolts and

flywheel.

Sst 09960–10010 (09962–01000, 09963–01000)

6. Remove drive plate & ring gear sub–assy (a/t transaxle)

- Fix the crankshaft with sst, then remove the 8 bolts and

drive plate & ring gear.

Sst 09960–10010 (09962–01000, 09963–01000)

7. Remove engine rear oil seal

- Using a knife, cut off the oil seal lip.

- using a screwdriver with taping its tip, pry out the oil seal.

Notice

: after the removal, check if the crankshaft is not damaged.

If there is, mend it with a sandpaper (#400).

8. Install engine rear oil seal

- Apply mp grease to a new oil seal lip.

Notice

: keep the lip off foreign materials.

- using sst, tap in the oil seal until its surface is flush with

the rear oil seal retainer edge.

Sst 09223–15020, 09950–70010 (09951–07100)

Notice

: wipe off extra grease on the crankshaft.

9. Install flywheel sub–assy (m/t transaxle)

- Fix the crankshaft with sst.

Sst 09960–10010 (09962–01000, 09963–01000)

- Clean the bolt and bolt hole.

- apply adhesive to the bolts.

Adhesive: part no. 09330–00070, Three bond or equivalent.

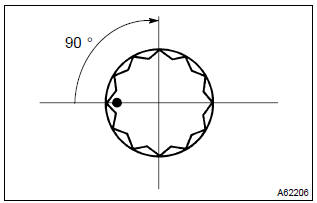

- install and uniformly tighten the 8 bolts, in several passes,

in the sequence shown.

Torque: 49 nvm (500 Kgf·cm, 36 ft·lbf)

- Mark the bolts with paint.

- retighten the bolts by an additional 90 .

- check that the point marked bolts are moved at 90 angle.

10. Install clutch disc assy (m/t transaxle) sst 09301–00210

11. Install clutch cover assy (m/t transaxle)

12. Install drive plate & ring gear sub–assy (a/t transaxle)

- Fix the crankshaft with sst.

Sst 09960–10010 (09962–01000, 09963–01000)

- Clean the bolt and bolt hole.

- apply adhesive to the bolts.

Adhesive: part no. 09330–00070, Three bond or equivalent.

- install and uniformly tighten the 8 bolts, in several passes, in the sequence shown.

- fix the crankshaft with sst.

Torque: 88 nvm (897 Kgf·cm, 65 ft·lbf)

13. Install manual transaxle assy (m/t transaxle)

14. Install automatic transaxle assy (a/t transaxle)

Other materials:

PDA (Proactive driving assist)

When a detectable object

is detected, the

proactive driving assist

operates the brakes and

steering wheel to help prevent

the vehicle from

approaching too close to

the object.

WARNING

■For safe use

Driving safely is solely the responsibility

of the driver.

The proactive driving assist is

design ...

Cruise control

Preparation

Sst

Recomended tools

Equipment

...

Floor shift cable transmission control select

Replacement

Hint: components:

1. Remove air conditioner unit assy

Hint:

refer to the instructions for removal of the air conditioner unit assy.

2. Separate air bag sensor assy center

remove the 3 bolts, separate the airbag sensor assy center.

3. Remove exhaust pipe assy

4. Remo ...