Toyota Corolla (E120): Inspection procedure

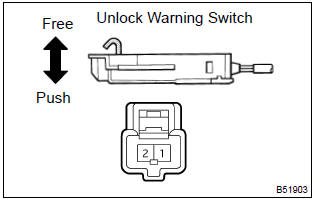

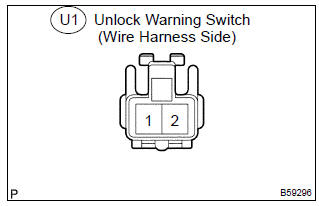

1 Check un–lock warning switch assy

- Disconnect the key unlock warning switch connector.

- check the continuity between the terminals of the key unlock warning switch connector, as shown in the illustration and table.

Standard:

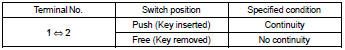

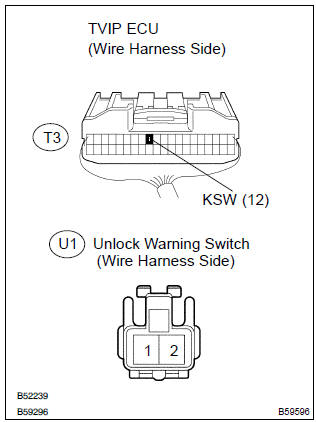

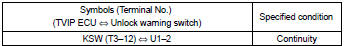

2 Check wire harness (tvip ecu unlock warning switch)

- Disconnect the tvip ecu and key unlock warning switch connectors.

- check the continuity between the terminals of the tvip ecu connectors and unlock warning switch connector, as shown in the illustration and table.

Standard:

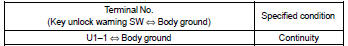

3 Check wire harness (key unlock warning switch body ground)

- Disconnect the key unlock warning switch connector.

- check the continuity between the terminal of the key unlock warning switch connector and the body ground, as shown in the illustration and table.

Standard:

Check and replace tvip ecu

Other materials:

Engine assembly

Inspection

1. Inspect coolant

2. Inspect engine oil

3. Inspect battery

4. Inspect air cleaner filter element sub–assy

5. Inspect spark plug

6. Inspect fan and generator v belt

Hint:

you don’t need to check the belt deflection because auto tensioner is adopted.

7. Inspect ignition ti ...

Cleaning and protecting the vehicle interior

Perform cleaning in a manner

appropriate to each

component and its material.

Protecting the vehicle

interior

Remove dirt and dust using a

vacuum cleaner. Wipe dirty

surfaces with a cloth dampened

with lukewarm water.

If dirt cannot be removed,

wipe it off with a soft cloth

dampened with neut ...

Using the AUX port

To use the AUX port, connect a portable player, press the “AUDIO” button,

then select “AUX” to display the audio control screen.

Connecting a portable audio player

■Operating portable audio players connected to the multimedia system

The volume can be adjusted using the vehicle' ...