Toyota Corolla (E120): Circuit inspection

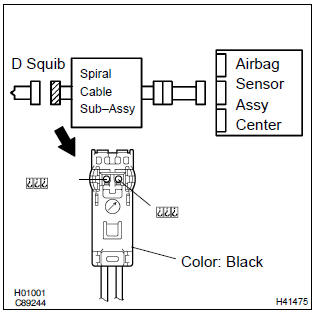

1 Check d squib circuit(airbag sensor assy center – horn button assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the horn button assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

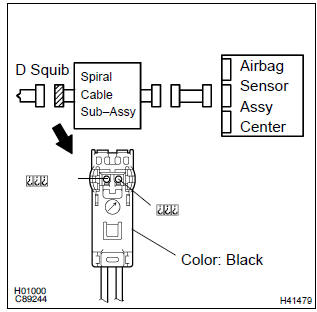

- for the black connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the voltage between d2+ and body

ground.

Ok: voltage: below 1 v

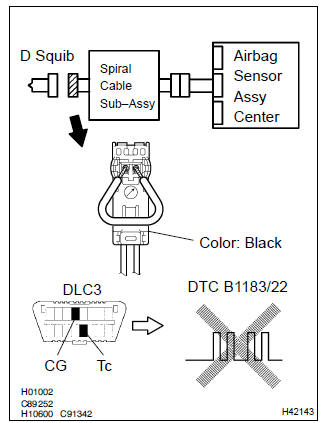

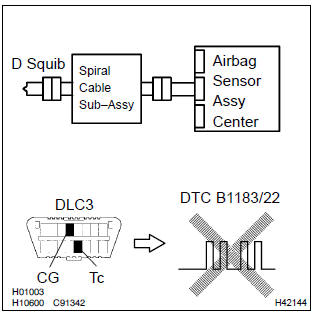

2 Check air bag sensor assy center

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the connector to the airbag sensor assy center.

- using a service wire, connect d2+ and d2– of the black connector (on the spiral cable sub–assy side) between the horn button assy and the spiral cable sub–assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1183/22 is not output.

Hint

: codes other than code b1183/22 may be output at this time, but they are not relevant to this check.

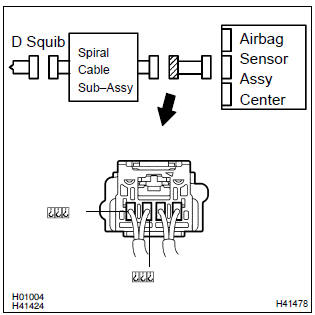

3 Check d squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the horn button assy connectors.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1183/22 is not output.

Hint

: codes other than code b1183/22 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

5 Check instrument panel wire(airbag sensor assy center – spiral cable sub–assy)

- Turn the ignition switch to lock.

- disconnect the connector of the instrument panel wire.

- turn the ignition switch to on.

- ) for the connector (on the spiral cable sub–assy side) between

the horn button assy and the spiral cable sub–assy,

measure the voltage between d2+ and body ground.

Ok: voltage: below 1 v

6 Check spiral cable sub–assy

- For the black connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the voltage between d2+ and body

ground.

Ok: voltage: below 1 v

7 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Displaying the device status

Select “Bluetooth* info” using .

● Displaying the device name

Select “Device Name” using .

● Displaying the device address

Select “Device Address” using .

*: Bluetooth is a registered trademark of Bluetooth SIG, Inc. ...

Ecm/pcm processor

Dtc p0606 ecm/pcm processor

Monitor description

The ecm continuously monitors its internal circuits. This self–check insures

that the ecm is functioning properly.

If a malfunction is detected, the ecm will set the appropriate dtc and

illuminate the mil.

The two cpus, main and sub cpu i ...

Inspection procedure

1 Check p/t squib(rh) circuit(airbag sensor assy center – front

seat outer belt assy rh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the seat belt pretensio ...