Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Engine coolant temperature circuit / Circuit description

Toyota Corolla (E120): Circuit description

A thermistor is built in the engine coolant temperature sensor and changes the resistance value according to the engine coolant temperature.

The structure of the sensor and connection to the ecm is the same as those of the intake air temperature sensor.

Hint

: if the ecm detects the dtc p0115, p0117 or p0118, it operates the fail–safe function in which the engine coolant temperature is assumed to be 80 c (176 °F).

|

Dtc no. |

Proceed to |

Dtc detection condition |

Trouble area |

| P0115 | Step 1 | Open or short in engine coolant temperature sensor circuit for 0.5 Seconds |

|

| P0117 | Step 4 | Short in engine coolant temperature sensor circuit for 0.5 Seconds | |

| P0118 | Step 2 | Open in engine coolant temperature sensor circuit for 0.5 Seconds |

Hint

: after confirming dtc p0115, p0117 or p0118, confirm the engine coolant temperature in the ”diagnosis/ enhanced obd ii/data list/all” using the hand–held tester or the obd ii scan tool.

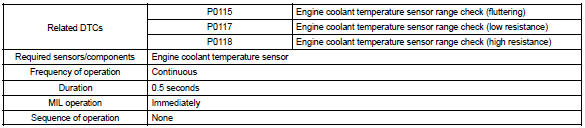

Monitor description

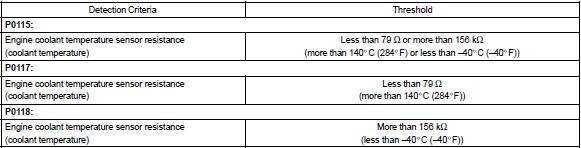

The engine coolant temperature (ect) sensor is used to monitor the engine coolant temperature. The ect sensor has a thermistor that varies its resistance depending on the temperature of the engine coolant. When the coolant temperature is low, the resistance in the thermistor increases. When the temperature is high, the resistance drops. The variations in resistance are reflected in the voltage output from the sensor. The ecm monitors the sensor voltage and uses this value to calculate the engine coolant temperature. When the sensor output voltage deviates from the normal operating range, the ecm interprets this as a fault in the ect sensor and sets a dtc.

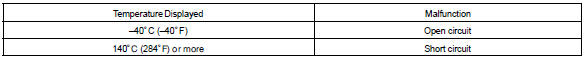

Example: when the ecm calculates that the ect is –40 c (–40 °F), or more than 140 c (284 °F), and if either the condition continues for 0.5 Sec or more, the ecm will set a dtc.

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

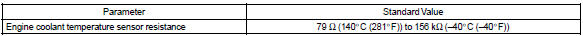

Component operating range

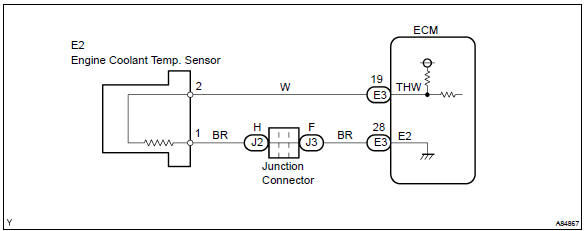

Wiring diagram

Other materials:

Wiring

Power source

Location

...

Thermostat

Replacement

1. Remove engine under cover rh

2. Drain coolant

3. Remove fan and generator v belt

4. Remove generator assy

Disconnect the wire clamp from the wire clip on the rectifire

end frame.

remove the rubber cap and nut, and disconnect the alternator

wire.

d ...

Circuit description

Hint:

these dtcs indicate a malfunction related to the primary circuit.

If dtc p0351 is displayed, check the no.1 Ignition coil with igniter

circuit.

If dtc p0352 is displayed, check the no.2 Ignition coil with igniter

circuit.

If dtc p0353 is displayed, check the no.3 Ignition coil ...