Toyota Corolla (E120): Overhaul

Hint

: components:

1. Discharge refrigerant from refrigeration system

sst 07110–58060 (07117–58080, 07117–58090, 07117–78050, 07117–88060, 07117–88070, 07117–88080)

2. Disconnect cooler refrigerant liquid pipe a

- Remove the bolt and disconnect the cooler refrigerant liquid pipe a from the w/receiver condenser assy.

- remove the o–ring from the cooler refrigerant liquid pipe a.

Notice

: seal the opening of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering.

3. Disconnect discharge hose sub–assy

- Remove the bolt and discharge hose sub–assy from the w/receiver condenser assy.

- remove the o–ring from the discharge hose sub–assy.

Notice

: seal the opening of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering.

4. Remove w/receiver condenser assy

- Remove the 2 bolts and 2 radiator upper supports.

- Remove the 2 bolts.

- slide the upper part of the radiator assy rearward to remove the w/receiver condenser assy.

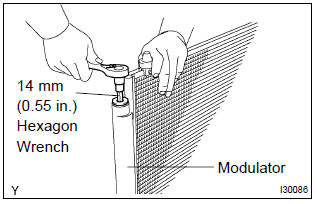

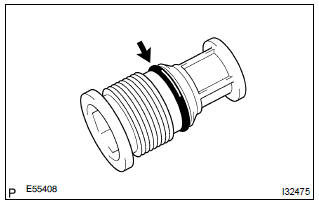

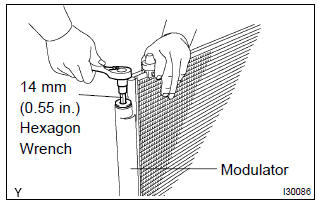

5. Remove cooler dryer

- Using a socket hexagon wrench 14 mm (0.55 In.), Remove the cap from the modulator.

- Remove the o–ring from the cap.

- Using pliers, remove the cooler dryer.

6. Install cooler dryer

- using pliers, install the cooler dryer.

- Install the new o–ring to the cap.

- sufficiently apply compressor oil to the fit surfaces of the

o–ring and the cap.

Compressor oil: nd–oil 8 or equivalent

- Using a socket hexagon wrench 14 mm (0.55 In.), Install

the cap to the modulator.

Torque: 2.9 Nvm (29 kgfvcm, 25 in.Vlbf)

7. Install w/receiver condenser assy

- Install the w/receiver condenser assy with the 2 bolts.

Torque: 9.8 Nvm (100 kgfvcm, 87 in.Vlbf)

- Install the 2 radiator upper supports with the 2 bolts.

8. Install discharge hose sub–assy

- remove the attached vinyl tape from the hose and connecting part of the w/receiver condenser assy.

- sufficiently apple compressor oil to the new o–ring and

hose joint.

Compressor oil: nd–oil 8 or equivalent

- install a o–ring to the discharge hose sub–assy.

- Install the discharge hose sub–assy to the w/receiver

condenser assy with the bolt.

Torque: 5.4 Nvm (54 kgfvcm, 48 in.Vlbf)

9. Install cooler refrigerant liquid pipe a

- remove the attached vinyl tape from the pipe and w/receiver condenser assy.

- sufficiently apple compressor oil to the new o–ring and

pipe joint.

Compressor oil: nd–oil 8 or equivalent

- install a o–rings to the cooler refrigerant liquid pipe a.

- Install the cooler refrigerant liquid pipe a to the w/receiver

condenser assy with the bolt.

Torque: 5.4 Nvm (54 kgfvcm, 48 in.Vlbf)

10. Charge refrigerant

sst 07110–58060 (07117–58060, 07117–58070, 07117–58080, 07117–58090, 07117–78050, 07117–88060, 07117–88070, 07117–88080), 07117–48130, 07117–48140 specified amount: 490 30 g (17.28 1.06 Oz.)

11. Warm up engine

12. Inspect leakage of refrigerant

Other materials:

Exterior/interior trim

Preparation

Recomended tools

Equipment

Vehicle control system

Preparation

Recomended tools

...

Circuit description

The d squib circuit consists of the airbag sensor assy center, spiral cable

sub–assy and horn button assy.

It causes the srs to deploy when the srs deployment conditions are satisfied.

Dtc b1180/17 is recorded when a short is detected in the d squib circuit (2nd

step).

Wiring diagra ...

Malfunction in water temperature receiver gauge

Wiring diagram

Inspection procedure

1 Read value of hand–held tester

Check output value of ecm.

Connect the hand–held tester to dlc3.

Turn the ignition switch to on and push the hand–held tester main

switch on.

Select the data list mode on the hand–he ...