Toyota Corolla (E120): Inspection procedure

1 Check airbag sensor assy center connector

- Disconnect negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- check the connection of the airbag sensor assy center connectors.

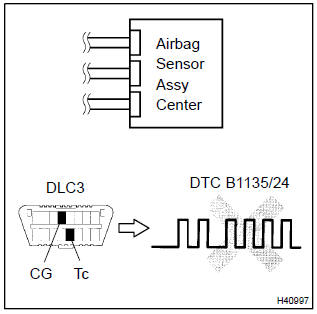

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- ) turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1135/24 is not output.

Hint

: codes other than code b1135/24 may be output at this time, but they are not relevant to this check.

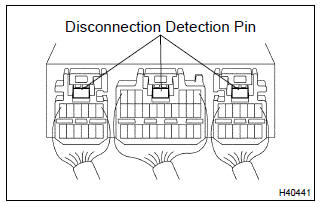

3 Check perform a visual check of the disconnection detection pin

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- with 3 connectors connected to the airbag sensor assy

center, place tester leads onto any 2 of 3 disconnection

detection pins and check for continuity.

Ok: continuity

Replace air bag sensor assy center

Other materials:

Selecting tire chains

Use the correct tire chain size when mounting the tire chains.

Chain size is regulated for each

tire size.

Side chain (0.12 in. [3 mm] in

diameter)

Side chain (0.39 in. [10 mm]

in width)

Side chain (1.18 in. [30 mm]

in length)

Cross chain (0.16 in. [4 mm]

in diameter)

Cross chain (0.55 i ...

Light control switch circuit

Wiring diagram

Inspection procedure

1 Check headlamp dimmer switch assy (light control switch)

2 Check wire harness (tvip ecu light control switch)

Disconnect the tvip ecu and light control switch connectors.

check the continuity between the terminals of the tvip

e ...

Inspection procedure

1 Inspect stop lamp switch assy

2 Check harness and connector(stop lamp switch assy – ecm)

Install the stop lamp switch assy.

disconnect the ecm connector.

measure the voltage according to the value(s) in the table

below when the brake pedal is depressed and rele ...