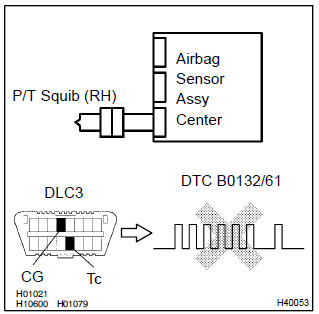

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p/t squib (rh) circuit (to

ground) / Inspection procedure

Toyota Corolla (E120): Inspection procedure

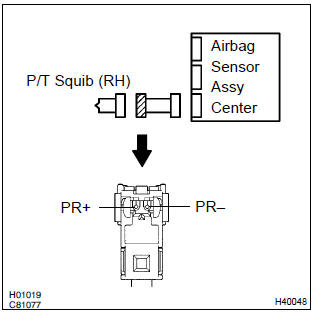

1 Check p/t squib(rh) circuit(airbag sensor assy center – front seat outer belt assy rh)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the seat belt pretensioner (rh).

- for the connector (on the seat belt pretensioner side) between

the airbag sensor assy center and the seat belt pretensioner

(rh), measure the resistance between pr+

and body ground.

Ok: resistance: 1 mΩ or higher

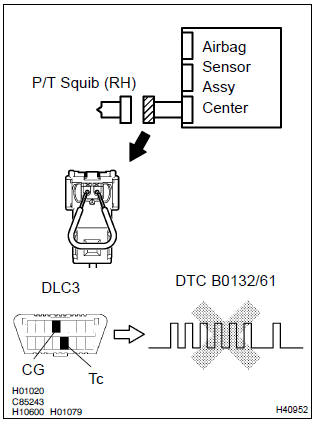

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- using a service wire, connect pr+ and pr– of the connector (on the seat belt pretensioner side) between the airbag sensor assy center and the seat belt pretensioner (rh).

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0132/61 is not output.

Hint

: codes other than code b0132/61 may be output at this time, but they are not relevant to this check.

3 Check p/t squib (rh)

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the seat belt pretensioner (rh) connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0132/61 is not output.

Hint

: codes other than code b0132/61 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Inspection and adjustment procedure

1 Tire valve

2 Tire pressure gauge

1 Remove the tire valve cap.

2 Press the tip of the tire pressure gauge onto the tire valve.

3 Read the pressure using the gauge gradations.

4 If the tire inflation pressure is not at the recommended level, adjust the pressure.

If you add too much air, pres ...

Inspection procedure

1 Inspect dlc3 terminal voltage(ts terminal)

Turn the ignition switch to on.

measure voltage between terminals ts and cg of dlc3.

Ok:

voltage: 10 – 14 v

2 Check harness and connector(dlc3 – body ground)

Check for open and short circuit in harness and connector between

...

Continuously variable transmission

(vehicles with paddle shift

switches)

Select the shift position

depending on your purpose

and situation.

Shift position purpose

and functions

P - Parking the vehicle/

starting the engine

R - Reversing

N - Neutral

(Condition in which the

power is not transmitted)

D - Normal driving*

M - 10-speed sport sequential

shiftmatic mode driving

* ...