Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Ignition coil primary/secondary

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

1 Perform simulation test

- Clear the dtc

- shuffle arrangement of the ignition coil and igniters.

Notice

: do not shuffle the connectors.

- perform the simulation test.

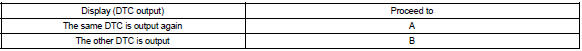

Result:

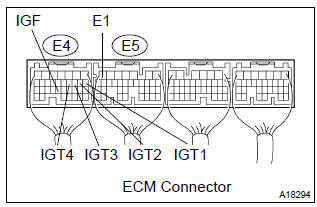

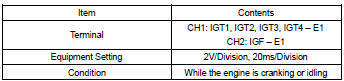

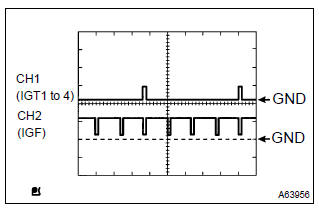

2 Inspect ecm(igt1, igt2, igt3, igt4 and igf signal)

- Inspection using the oscilloscope.

- during cranking or idling, check the waveform between terminals igt1 to igt4 and e1, igf and e1 of the ecm connector.

Standard:

Hint

: correct waveform is as shown in the diagram on the left.

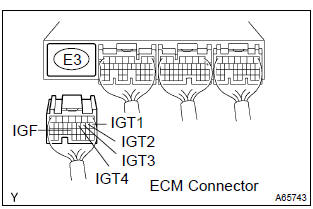

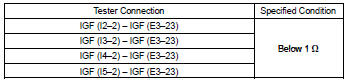

3 Check harness and connector(ignition coil assy – ecm)

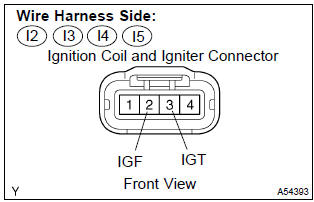

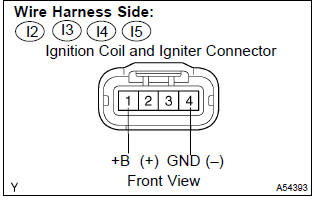

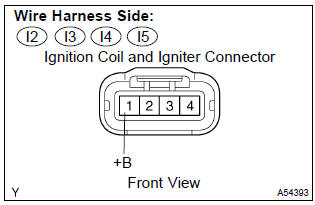

- Disconnect the i2, i3, i4 or i5 ignition coil and igniter connector.

- disconnect the e3 ecm connector.

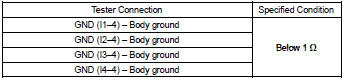

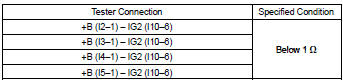

- check the resistance between the wire harness side connectors.

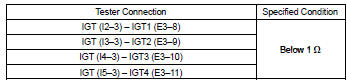

Standard (check for open):

Standard (check for open):

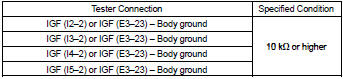

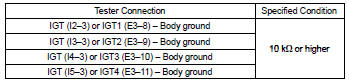

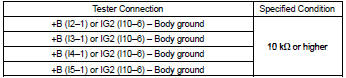

Standard (check for short):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the ignition coil and igniter connector

4 Inspect ignition coil assy(power source)

- Disconnect the i2, i3, i4 or i5 ignition coil and igniter connector.

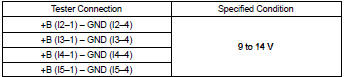

- check the resistance between the wire harness side connectors.

Standard (check for open):

- Turn the ignition switch on position.

- measure the voltage between the terminal of the wire harness side connector and body ground.

Standard:

- Reconnect the ignition coil and igniter connector.

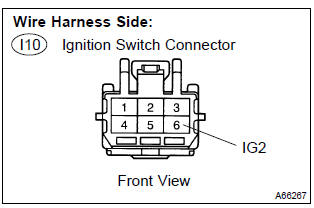

5 Check harness and connector(ignition coil assy – ignition switch)

- Disconnect the i2, i3, i4 or i5 ignition coil and igniter connector.

- disconnect the i10 ignition switch connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the ignition coil and igniter connector.

- reconnect the ignition switch connector.

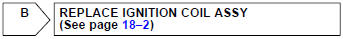

Replace ignition coil assy

Other materials:

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...

Listing the registered cellular phones

Select “List Phone” using .

The list of registered cellular phones will be displayed.

● Connecting the registered cellular phone to the audio system

1 Select the name of the cellular phone to be connected using

.

2 Select “Select” using .

● Deleting a registered cell ...

Replacement

Hint: components:

1. Remove radiator grille sub–assy

2. Remove front bumper cover

3. Remove lh headlamp assy

Remove the 3 bolts.

pull out the headlight assy lh forward, then disconnect

the bracket of body side.

Release the claws and disconnect the connectors as

sh ...