Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Intake air temperature circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

:

- if different dtcs related to different systems that have terminal e2 as the ground terminal are output simultaneously, terminal e2 may be open.

- Read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

1 Read value of hand–held tester or obd ii scan tool(intake air temperature)

- Connect the hand–held tester or the obd ii scan tool to the dlc3.

- turn the ignition switch on and push the hand–held tester or the obd ii scan tool main switch on.

- select the item ”diagnosis / enhanced obd ii / data list / all / intake air” and read its value displayed on the hand–held tester or the obd ii scan tool.

Temperature: same value as the actual intake air temperature.

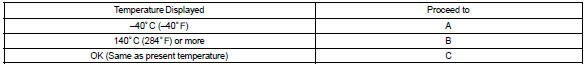

Result:

Hint

:

- if there is an open circuit, the hand–held tester or the obd ii scan tool indicates –40 °C (–40°f).

- If there is a short circuit, the hand–held tester or the obd ii scan tool indicates 140 °C (284°f) or more.

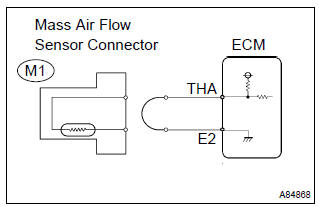

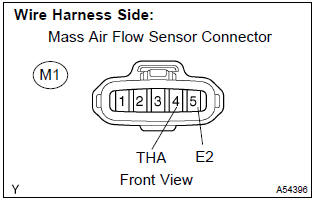

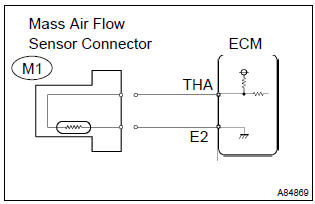

2 Read value of hand–held tester or obd ii scan tool(check for open in wire harness)

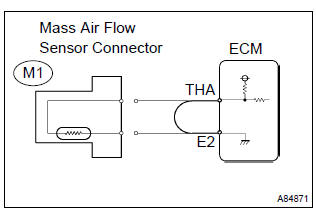

- Disconnect the m1 mass air flow sensor connector

- connect terminals tha and e2 of the mass air flow sensor wire harness side connector.

- turn the ignition switch on.

- select the item ”diagnosis / enhanced obd ii /

data list / all / intake air” and read its value displayed

on the hand–held tester or the obd ii scan tool.

Temperature value: 140 °C (284°f) or more

- reconnect the mass air flow sensor connector.

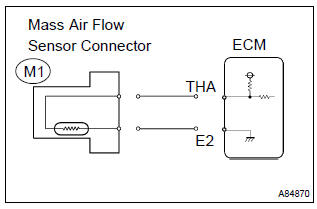

3 Read value of hand–held tester or obd ii scan tool(check for open in ecm)

- Disconnect the m1 mass air flow sensor connector.

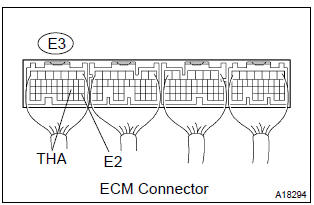

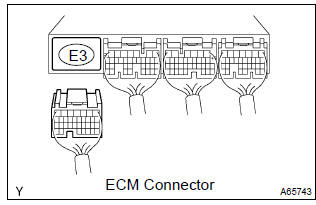

- connect the terminals tha and e2 of the e3 ecm connector.

Hint

: before checking, do a visual and contact pressure check on the ecm connector.

- turn the ignition switch on.

- select the item ”diagnosis / enhanced obd ii /

data list / all / intake air” and read its value displayed

on the hand–held tester or the obd ii scan tool.

Temperature value: 140 °C (284°f) or more

- reconnect the mass air flow sensor connector.

Confirm good connection at ecm. If ok, replace ecm

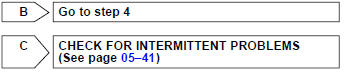

4 Read value of hand–held tester or obd ii scan tool(check for short in wire harness)

- Disconnect the m1 mass air flow sensor connector.

- turn the ignition switch on.

- select the item ”diagnosis / enhanced obd ii /

data list / all / intake air” and read its value displayed

on the hand–held tester or the obd ii scan tool.

Temperature value: –40 °C (–40°f)

- reconnect the mass air flow sensor connector.

5 Read value of hand–held tester or obd ii scan tool(check for short in ecm)

- Disconnect the e3 ecm connector.

- turn the ignition switch on.

- select the item ”diagnosis / enhanced obd ii /

data list / all / intake air” and read its value displayed

on the hand–held tester or the obd ii scan tool.

Temperature value: –40 °C (–40°f)

- reconnect the ecm connector.

Replace ecm

Other materials:

Selecting, fast-forwarding and reversing tracks/files/songs

■ Selecting a track/file/song

Press the “∧” or “∨” button on “SEEK/TRACK” or turn the “TUNE/ SCROLL” knob

to select the desired track/file/song number.

To fast-forward or reverse, press and hold the “∧” or “∨” button on “SEEK/TRACK”.

...

How to proceed with troubleshooting

The hand–held tester can be used at step 3, 4, 5, 7, 10.

1 Vehicle brought to workshop

2 Customer problem analysis

3 Connect hand–held tester to dlc3

Hint:

if the display indicates a communication fault in the tool, inspect dlc3.

4 Check dtc and freeze frame data

Hint:

record or pr ...

Transmission valve body assy (atm)

Replacement

1. Remove engine under cover lh

2. Drain automatic transaxle fluid

remove the drain plug, gasket and drain atf.

install a new gasket and drain plug.

Torque: 17.5 Nvm (178 Kgf·cm, 13 ft·lbf)

3. Remove automatic transaxle oil pan sub–assy

Remove the 18 ...