Toyota Corolla (E120): Inspection

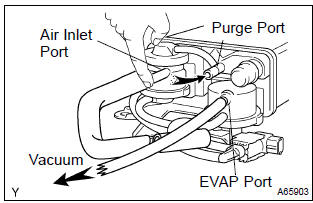

1. Charcoal canister assy

- Visually check the charcoal canister for cracks or damage.

- Inspect the charcoal canister operation.

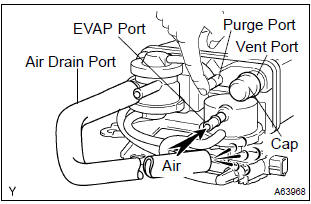

- Plug the vent port with the cap.

- While holding the purge port closed, blow air (1.76 Kpa, 18 gf/cm2, 0.26 Psi) into the evap port and check that air flows from the air drain port.

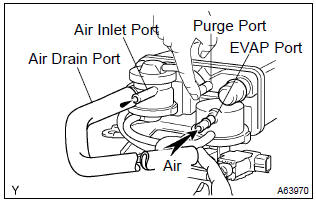

- While holding the purge port and the air drain port closed, blow air (1.76 Kpa, 18 gf/cm2, 0.26 Psi) into the evap port and check that air does not flow from the air inlet port.

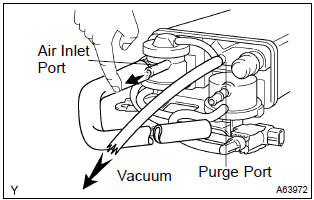

- Apply vaccum (3.43 Kpa, 25.7 Mmhg, 1.01 In.Hg) to the purge port, check that the vacuum dose not decrease when the air inlet port is closed, and check that the vacuum decreases when the air inlet port is released.

- While holding the air inlet port closed, apply vacuum

(3.43 Kpa, 25.7 Mmhg, 1.01 In.Hg) to the evap port

and check that air flows into the purge port.

If operation is not as spacified, replace the charcoal canister.

- Remove the hose and cap from vent port.

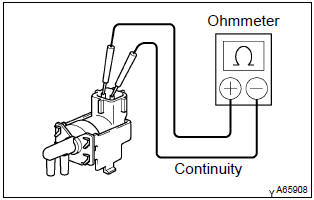

- Inspect vsv for pressure swiching valve

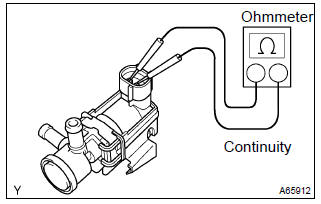

- using an ohmmeter, check that there is continuity

between the terminals.

Resistance: 37 – 44 w at 20 c (68 f) if there is no continuity, replace the vsv.

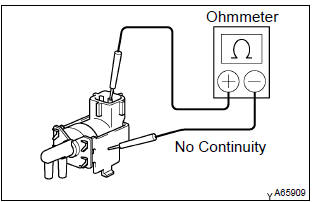

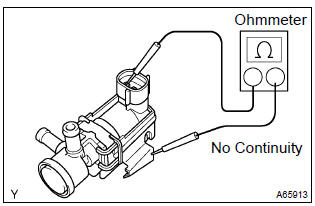

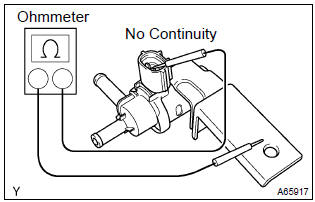

- Using an ohmmeter, check that there is no continuity

between each terminal and the body.

If there is continuity, replace the vsv.

- Check that air does not flow from ports e to f.

- Apply battery positive voltage across the terminals.

- Check that air flows from ports e to f.

If operation is not as specified, replace the vsv.

2. Ventilation valve sub–assy

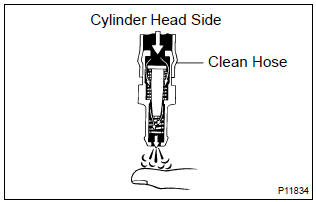

- Install clean hose to the pcv valve.

- inspect the pcv valve operation.

- Blow air into the cylinder head side, and check that air passes through easily.

Caution

: do not suck air through the valve. Petroleum substances inside the valve air harmful.

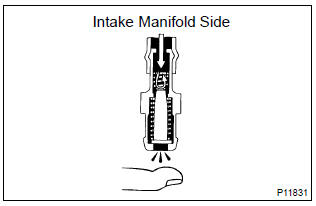

- Blow air into the intake manifold side, and check

that air passes through with difficulty.

If operation is not as specified, replace the pcv valve.

- remove clean hose from the pcv valve.

3. Fuel tank cap assy

- Visually check if cap and/or gasket are deformed or damaged.

If necessary, repair or replace the cap.

4. Vacuum switching valve no.1

- Inspect vsv for evaporative emission (evap).

- Using an ohmmeter, check that there is continuity

between the terminals.

Resistance: 27 – 33 Ω at 20 c (68 f) if there is no continuity, replace the vsv.

- Using an ohmmeter, check that there is no continuity

between each terminal and the body.

If there is continuity, replace the vsv.

- Check that air flows from ports e to f.

- Apply battery positive voltage across the terminals.

- Check that air does not flow from ports e to f.

If operation is not as specified, replace the vsv.

5. Vacuum switching valve assy no.1

- Inspect vsv for canister closed valve (ccv).

- Using an ohmmeter, check that there is continuity

between the terminals.

Resistance: 25 – 30 Ω at 20 c (68 f) if there is no continuity, replace the vsv.

- Using an ohmmeter, check that there is no continuity

between each terminal and the body.

If there is continuity, replace the vsv.

- Check that air flows from ports a to b.

- Apply battery positive voltage across the terminals.

- Check that air does not flow from ports a to b.

If operation is not as specified, replace the vsv.

Other materials:

Fail–safe chart

If any of the following codes is recorded, the ecm enters the fail–safe mode.

Check for intermittent problems

Hand–held tester only:

by putting the vehicle’s ecm in the check mode, the 1 trip detection logic is

possible instead of the

2 trip detection logic, and the sensitivity to de ...

Replacement

1. Drain engine oil

remove the oil pan drain plug and drain the engine oil.

2. Removal & installation chain sub–assy

3. Remove chain vibration damper no.1

remove 2 bolts and chain vibration damper no. 1.

4. Remove oil pump assy

Remove the 5 bolts.

rem ...

Locking the doors from the outside without a key

1 Move the inside lock button to the lock position.

2 Close the door.

► Vehicles without a smart key system

The door cannot be locked if either of the front doors is open and the key is in

the engine switch.

► Vehicles with a smart key system

The door cannot be locked if the engin ...