Toyota Corolla (E120): Hydraulic test

1. Perform hydraulic test

- Measure the line pressure.

Notice

:

- Do the test at normal operation atf temperature 50 to 80 °c (122 to 176 °f).

- The line pressure test should always be carried out in pairs. One technician should observe the conditions of wheels or wheel stopper outside the vehicle while the other is doing the test.

- Be careful to prevent sst’s hose from interfering with the exhaust pipe.

- Warm up the atf.

- Remove the test plug on the transaxle case front left

side and connect sst.

Sst 09992–00095 (09992–00231, 09992–00271)

- fully apply the parking brake and chock the 4 wheels.

- Connect an obd ii scan tool or hand–held tester to the dlc3.

- Start the engine and check the idling speed.

- Keep your left foot pressed firmly on the brake pedal and shift into the d position.

- Measure the line pressure when the engine is idling.

- Depress the accelerator pedal all the way down.

Quickly read the highest line pressure when the engine speed reaches the stall speed.

- Do the test in the r position in the same way.

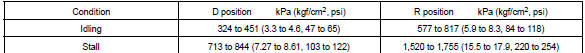

Specified line pressure:

Evaluation:

|

Problem |

Possible cause |

| If the measured values at all positions are higher |

|

| If the measured values at all positions are lower |

|

| If pressure is low in the d position only |

|

| If pressure is low in the r position only |

|

Other materials:

Exterior/interior trim

Preparation

Recomended tools

Equipment

Vehicle control system

Preparation

Recomended tools

...

Adding a new phone number

Select “Add contacts” using . ●

Transferring all contacts from the cellular phone

Select “Overwrite all contacts” using

and press

(YES).

● Transferring one contact from the cellular phone

Select “Add one contact” using and

press (YES). ...

Engine immobilizer system

The vehicle’s keys have built-in transponder chips that prevent the engine

from starting if a key has not been previously registered in the vehicle’s on-board

computer.

Never leave the keys inside the vehicle when you leave the vehicle.

Vehicles without a smart key system: The indicator li ...