Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Readiness monitor drive pattern / Evap monitor (vacuum pressure monitor) (continued)

Toyota Corolla (E120): Evap monitor (vacuum pressure monitor) (continued)

- Preconditions

The monitor will not run unless:

- mil is off.

- Fuel level is approximately 1/2 to 3/4.

- Altitude is 7800 feet (2400 m) or less.*

- Engine coolant temperature (ect) is between 40°f and 95°f (4.4 °C and 35 °C).

- Intake air temperature (iat) is between 40°f and 95 °f (4.4 °C and 35 °C).*

- Cold soak procedure has been completed.

- Before starting the engine, the difference between ect and iat must be less than 13°f (7 °C).

Hint

:

examples:

- scenario 1

ect = 75°f (24 °C)

iat = 60°f (16 °C)

difference between ect and iat is 15°f (8 °C).The monitor will not run because difference between ect and iat is greater than 13°f (7 °C).

- Scenario 2

ect = 70°f (21 °C)

iat = 68°f (20 °C)

difference between ect and iat is 2°f (1 °C).The monitor will run because difference between ect and iat is less than 13°f (7 °C).

Notice

: * note for 2002 and later my vehicles: the readiness test can be completed in cold ambient conditions (less than 40°f / 4.4 °C) and/or at high altitudes (more than 7800 feet / 2400 m) if the drive pattern is repeated a second time after cycling the ignition off.

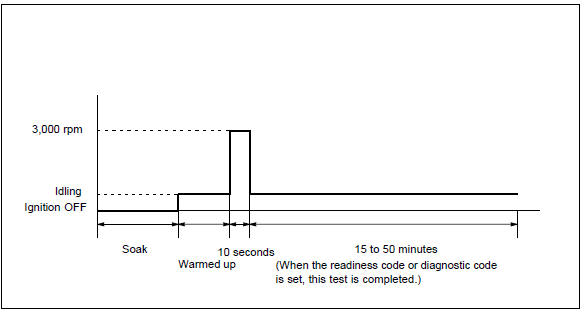

- Drive pattern

- connect the obd ii scan tool to dlc3 to check monitor status and preconditions.

- Release pressure in the fuel tank by removing and then reinstalling the fuel tank cap.

- Start the engine and allow it to idle until ect becomes 167°f (75 °C) or greater.

- Run the engine at 3,000 rpm for about 10 seconds.

- Allow the engine to idle with the a/c on (to create slight load) for 15 to 50 minutes.

Notice

: if the vehicle is not equipped with a/c put a slight load on the engine by doing the following :

- securely set the parking brake.

- Block the drive wheels with wheel chocks.

- Allow the vehicle to idle in drive for 15 to 50 minutes.

Other materials:

Connecting a Bluetooth® device

Up to 5 Bluetooth® devices (Phones (HFP) and audio players (AVP)) can be registered.

If more than 1 Bluetooth® device has been registered, select which device to

connect to.

1 Press the “SETUP” button.

2 Select “Bluetooth*”.

*: Bluetooth is a registered trademark of Bluetooth SIG, In ...

Circuit description

The crankshaft position sensor (ne signal) consists of a magnet, iron core

and pickup coil.

The ne signal plate (crankshaft position sensor plate) has 34 teeth and is

installed on the crankshaft. The

ne signal sensor generates 34 signals for each engine revolution. This sensor

monitors a p ...

Circuit description

When the brake pedal is depressed, the stop lamp switch assy sends a signal

to the cruise control ecu assy.

When the cruise control ecu assy receives this signal, it cancels the cruise

control.

A fail–safe function is provided so that cancel functions normally, even if

there is a malfu ...