Toyota Corolla (E120): Data list/active test

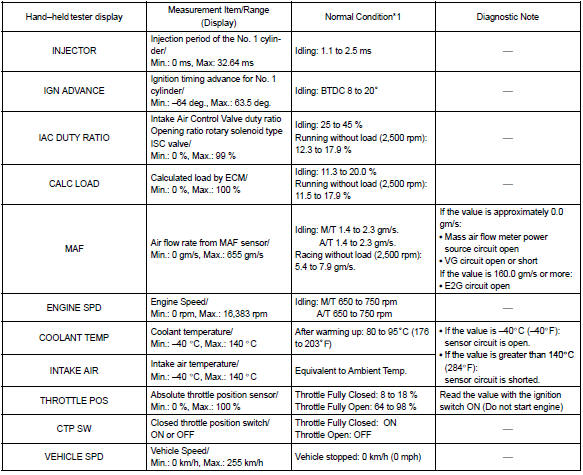

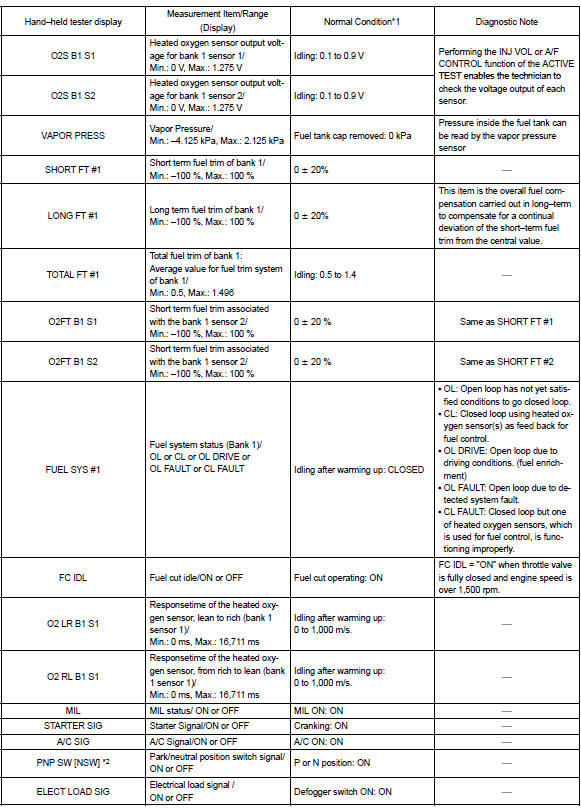

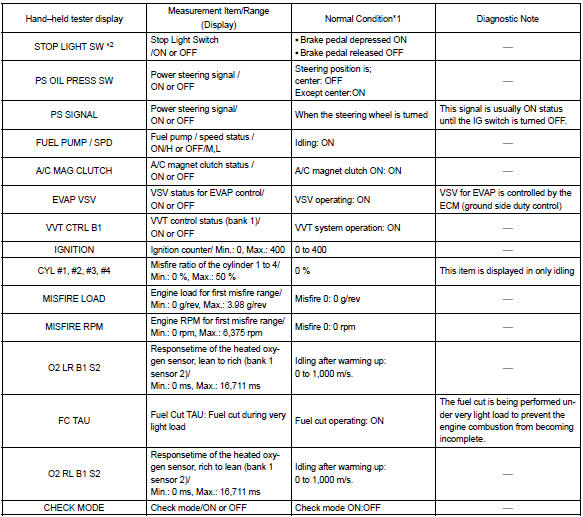

1. Data list

Hint

: using the data list displayed by the hand–held tester or the obd ii scan tool, you can read the value of the switches, sensors, actuators and so on without parts removal. Reading the data list as a first step of troubleshooting is one method to shorten diagnostic time.

Notice

: the values given below for ”normal condition” are representative values. A vehicle may still be normal even if its value differs from those listed here. Do not solely depend on the ”normal condition” here when deciding whether a part is faulty or not.

- Warm up the engine.

- turn the ignition switch off.

- connect the hand–held tester or the obd ii scan tool to the dlc3.

- turn the ignition switch on.

- push the ”on” button of the hand–held tester or the obd ii scan tool.

- select the item ”diagnosis / enhanced obd ii / data list”.

- according to the display on the tester, read the ”data list”.

*1: If no conditions are specifically stated for ”ldling”, it means the shift lever is in the n or p position, the a/c switch is off and all accessory switches are off.

*2: A/t only

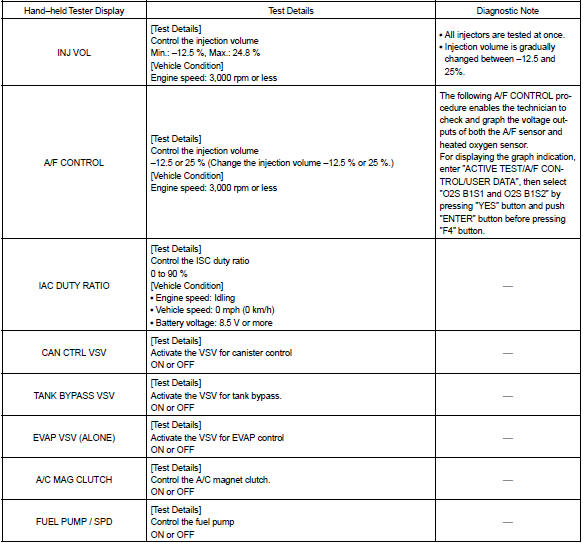

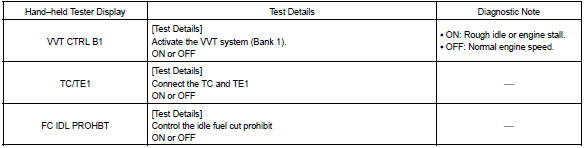

2. Active test

Hint

: performing the active test using the hand–held tester or the obd ii scan tool allows the relay, vsv, actuator and so on to operate without parts removal. Performing the active test as a first step of troubleshooting is one method to shorten diagnostic time.

It is possible to display the data list during the active test.

- warm up the engine.

- turn the ignition switch off.

- connect the hand–held tester or the obd ii scan tool to the dlc3.

- turn the ignition switch on.

- push the ”on” button of the hand–held tester or the obd ii scan tool.

- select the item ”diagnosis / enhanced obd ii / active test”.

- according to the display on the tester, perform the ”active test”.

Other materials:

Changing the engine switch positions

1 “LOCK”

The steering wheel is locked and the key can be removed. (Vehicles with an automatic

transmission or continuously variable transmission: The key can be removed only

when the shift lever is in P.) 2 “ACC”

Some electrical components such as the audio system can be used.

3 “ON ...

Inspection procedure

1 Inspect skid control ecu connector(+bs terminal voltage)

Disconnect the skid control ecu connector.

measure the voltage between terminals +bs (2) and gnd

(1, 23) of skid control ecu harness side connector.

Voltage: 10 – 14 v

2 Reconfirm dtc

Check the dtc .

Ok :

...

Replacement

1. Remove radiator grille sub–assy

2. Remove front bumper cover

3. Remove fog lamp assy lh

Remove a nut and release a claw.

remove the fog light assy lh.

4. Put vehicle these conditions

5. Adjust fog light aim

6. Check fog light aim ...