Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Electronic controlled automatic transaxle / Shift solenoid ”a” performance

(shift solenoid valve s1)

Toyota Corolla (E120): Shift solenoid ”a” performance (shift solenoid valve s1)

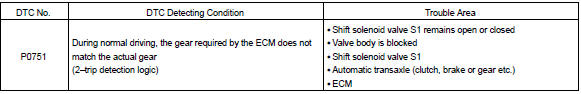

Dtc p0751 shift solenoid ”a” performance (shift solenoid valve s1)

System description

The ecm uses signals from the vehicle speed sensor and crankshaft position sensor to detect the actual gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual gear with the shift schedule in the ecm memory to detect the mechanical trouble of the shift solenoid valves, the valve body or automatic transaxle (clutch, brake or gear etc.).

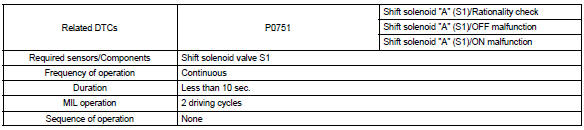

Monitor description

The ecm commands gear shifts by turning the shift solenoid valves ”on/off”. According to the input shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ecm detects the actual gear position (1st, 2nd, 3rd or o/d gear position). When the gear position commanded by the ecm and the actual gear position are not same, the ecm illuminates the mil.

Monitor strategy

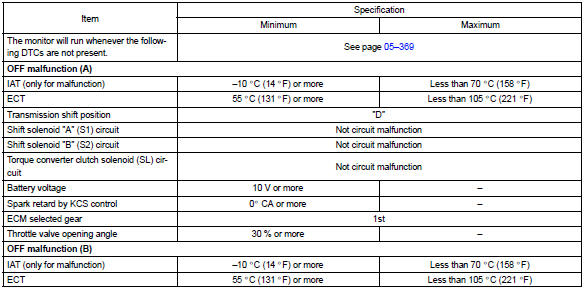

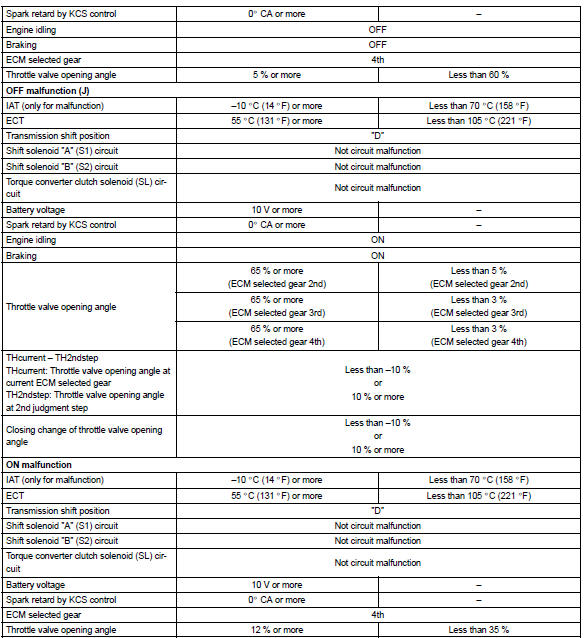

Typical enabling conditions

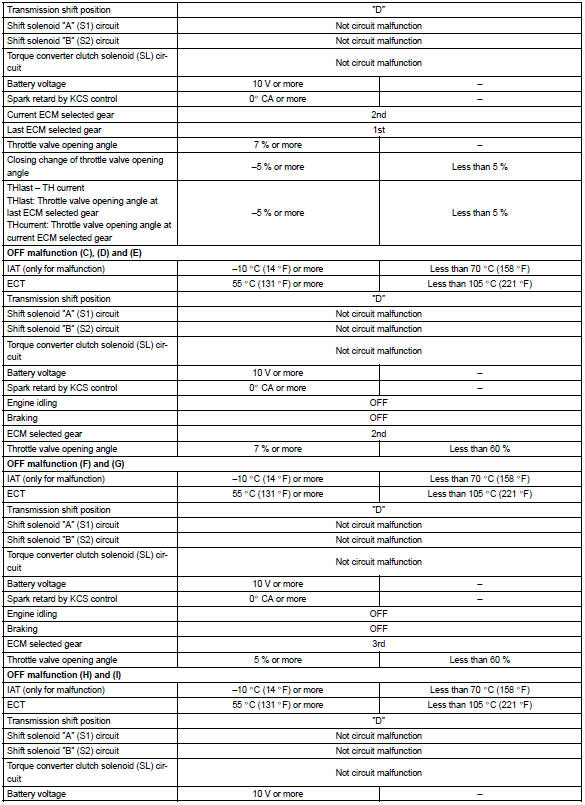

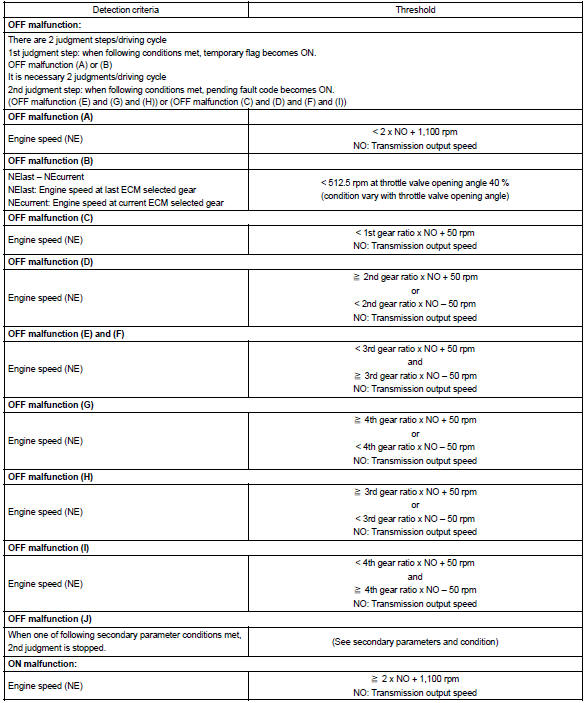

Typical malfunction thresholds

Other materials:

Exterior

Doors

Locking/unlocking

Opening/closing the side windows

Locking/unlocking by using the mechanical key*1

Warning messages

Trunk

Opening from inside

Opening from outside

Warning messages

Outside rear view mirrors

Adjusting the mirror angle

Folding the mirrors

Defogging the mirrors*2

...

Replacement

Hint:

installation is in the reverse order of the removal. But the installation is

indicated only when it has a point.

1. Remove radiator grille sub–assy

Remove the 2 bolts and clip.

using a screwdriver, remove the radiator grille.

Hint:

tape the screwdriver tip before use. ...

Replacement

1. Remove instrument panel sub–assy lower

2. Remove clutch pedal spring

3. Remove clutch master cylinder push rod clevis w/hole pin

Remove the clip and hole pin.

4. Remove clutch pedal support sub–assy

W/ cruise control:

disconnect the clutch switch assy connector.

&nbs ...