Toyota Corolla (E120): Overhaul

1. Remove speedometer drive (mtm) gear

- Remove the speedometer drive (mtm) gear from the front differential case.

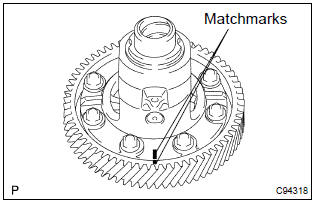

2. Remove front differential ring gear

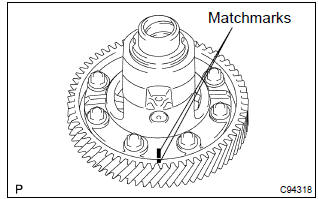

- Place matchmarks on the front differential ring gear and front differential case.

- Remove the 8 bolts. Using a hammer, remove the front differential ring gear.

3. Inspect front differential side gear backlash

- Fixing the front differential pinion from the front differential

case side. Using a dial indicator, measure the backlash of

the front differential side gear.

Standard backlash:

0.05 – 0.20 Mm (0.0020 – 0.0079 In.)

If the backlash is not within the specification, install the connect side gear thrust washers.

4. Remove front differential pinion shaft straight pin

- Using a chisel and a hammer, loosen the staked part of the front differential case.

- Using a pin punch (f 3 mm) and a hammer, remove the front differential pinion shaft straight pin from the front differential case.

5. Remove front differential pinion shaft no.1

- Remove the front differential pinion shaft no.1 From the front differential case.

6. Remove front differential side gear

- Remove the 2 front differential pinions, 2 front differential pinion thrust washers, 2 front differential side gear thrust washers and 2 front differential side gears from the front differential case.

Hint

: turning the front differential pinion, remove the 2 pinions and side gear.

7. Inspect front differential pinion thrust washer

- Using a micrometer, measure the thickness of the front

differential pinion thrust washer.

Minimum thickness: 0.92 Mm (0.0362 In.)

If the clearance is below the minimum, replace the front differential pinion thrust washer.

8. Inspect front differential pinion shaft no.1

- Using a micrometer, measure the the outer diameter of

the front differential pinion shaft no.1.

Minimum outer diameter: 16.982 Mm (0.6686 In.)

If the outer diameter is less than the minimum, replace the front differential pinion shaft no.1.

9. Install front differential side gear

- Coat the sliding and rotating surface of the 2 front differential side gears with mp grease.

- install the 2 front differential side gear thrust washers to the 2 front differential side gear.

Hint

: install the front differential side gear thrust washer that has the same thickness as the removed one.

- install the 2 front differential side gears, 2 front differential pinions and 2 front differential side gear thrust washers to the front differential case.

Hint

: turning the front differential pinion, install the 2 front differential pinions with front differential case.

10. Install front differential pinion shaft no.1

- Coat the rotating surface of the front differential pinion shaft no.1 With gear oil.

- install the front differential pinion shaft no.1 To the front differential case so that the hole for the front differential pinion shaft straight pin is aligned with the hole in the front differential case.

11. Adjust front differential side gear backlash

- Fixing the front differential pinion to the front differential

case side. Using a dial indicator, measure the front differential

side gear backlash.

Standard backlash:

0.05 – 0.20 Mm (0.0020 – 0.0079 In.)

If the backlash is out of specification, replace the side gear thrust washer.

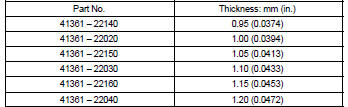

Thrust washer thickness:

Hint

:

- because the thrust washer does not have any identification mark, measure the front thickness with a micrometer to select a proper thrust washer.

- Select washers that has the same thickness as both the right and left.

12. Install front differential pinion shaft straight pin

- Using a pin punch (f 3 mm) and a hammer, install the front differential pinion shaft straight pin to the front differential case.

- Using a chisel and a hammer, stake the front case hole.

13. Install front differential ring gear

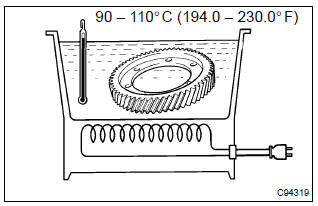

- Using a heater, heat the front differential ring gear to 90 – 110 c (194.0 – 230.0 F)

- clean the contact surface of the front differential case.

- Align the both matchmarks, quickly install the 8 bolts with

the front differential ring gear to the front differential case.

Torque: 77.4 Nvm (789 Kgf·cm, 57 ft·lbf)

14. Install speedometer drive (mtm) gear

- Install the speedometer drive (mtm) gear to the front differential case.

Other materials:

Dialing from call history

You can make a call using the call history, which has the 3 functions below.

: calls which you missed

: calls which you received

: calls which you made

1 Display the phone screen.

2 Select “Call History” tab.

3 Select or the desired entry from

the list.

► When

is selected

4 C ...

Using a top tether anchorage

(for Puerto Rico)

■ Top tether anchorages

Top tether anchorages are provided

for each rear seat.

Use top tether anchorages

when fixing the top strap.

Top tether anchorages

Top strap

■ Fixing the top strap to the

top tether anchorages

Install the child restraint system

in accordance to the operation

manual e ...

Replacement

Hint: components:

1. Remove rear wheel

2. Remove rear brake drum sub–assy

3. Disconnect skid control sensor wire (w/ abs)

4. Remove rear axle hub & bearing assy lh

Remove the 4 bolts and hub & bearing assy lh.

5. Install rear axle hub & bearing assy lh

Install t ...