Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p squib (2nd step) circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

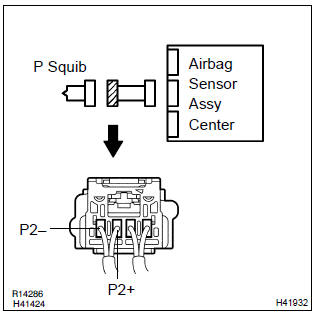

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the instrument panel passenger airbag assy.

- release the airbag activation prevention mechanism of the connector (on the airbag sensor assy center side) between the airbag sensor assy center and the instrument panel passenger airbag assy .

- for the connector (on the instrument panel passenger airbag

assy side) between the airbag sensor assy center

and the instrument panel passenger airbag assy, measure

the resistance between p2+ and p2–.

Ok: resistance: 1 mw or higher

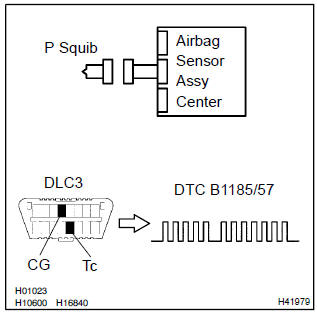

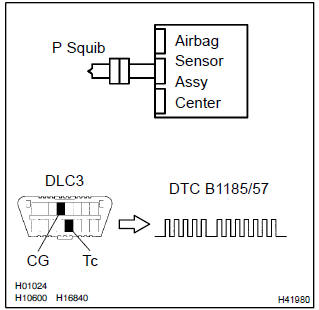

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1185/57 is not output.

Hint

: codes other than code b1185/57 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1185/57 is not output.

Hint

: codes other than code b1185/57 may be output at this time, but they are not relevant to this check.

Use simulation method to check

Other materials:

Replacement

Hint:

installation is according to the reverse order of the removal.

1. Remove rear door weatherstrip rh

2. Remove rear door weatherstrip lh

3. Remove rear seat cushion assy (, 72–8)

4. Remove rear seat back assy (fixed type rear seat)

5. Remove separate type rear seat back assy (separate ...

License plate lamp assy

Replacement

1. Remove luggage compartment lock cylinder & key set

2. Remove luggage compartment door garnish outside

3. Remove license plate lamp assy

Pull the license plate light assy to the side of vehicle as

shown in the illustration and release the claw.

disconnect the c ...

Registering ID codes

(vehicles with a tire pressure

warning system)

The tire pressure warning valve

and transmitter is equipped with

a unique ID code. When new

tire pressure warning valves and

transmitters are installed, new

ID codes must be registered in

the tire pressure warning computer.

ID codes can be registered by

yourself, but depending on

the driving con ...