Toyota Corolla (E120): Inspection procedure

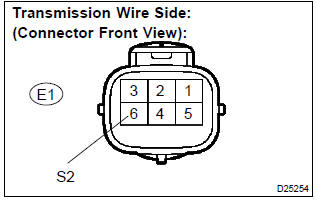

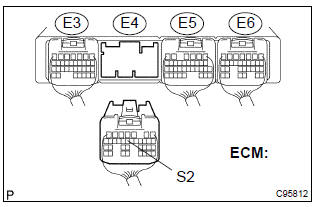

1 Inspect transmission wire(s2)

- Disconnect the transmission wire connector from the transaxle.

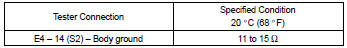

- measure the resistance according to the value(s) in the table below.

Standard:

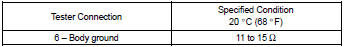

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission connector to the transaxle.

- disconnect the connector from the ecm.

- measure the resistance according to the value(s) in the table below.

Standard:

Replace ecm

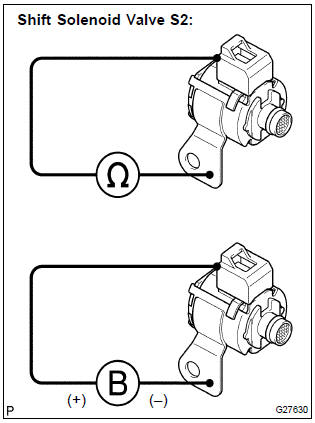

3 Inspect shift solenoid valve(s2)

- Remove the shift solenoid valve s2.

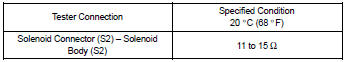

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead to the solenoid connector terminal, and the negative (–) battery lead to the solenoid body for checking the solenoid valve operation.

Standard: the solenoid makes an operating noise.

Repair or replace transmission wire

Other materials:

How to register a Bluetooth® device

1 Display the “Bluetooth* Setup” screen. *: Bluetooth is a registered trademark

of Bluetooth SIG, Inc.

2 Select “Add”.

3 When this screen is displayed, search for the device name displayed on this

screen on the screen of your Bluetooth® device.

For details about operating the Bluetoo ...

Headlamp dimmer switch assy

Replacement

1. Remove steering column cover lwr

Remove 3 screws and steering column cover lwr.

2. Remove headlamp dimmer switch assy

Disconnect the connector.

release the claw and pull out the head light dimmer

switch assy.

...

Circuit description

The vapor pressure sensor and the vsv for the canister closed valve (ccv) are

used to detect abnormalities

in the evaporative emission control system. The ecm decides whether there is an

abnormality in the evaporative

emission control system based on the vapor pressure sensor signal.

Dtc p0 ...