Toyota Corolla (E120): Inspection

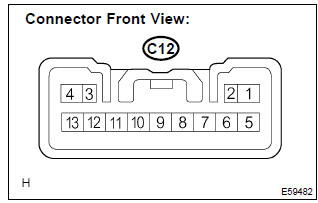

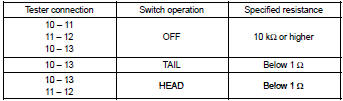

1. Headlamp dimmer switch assy

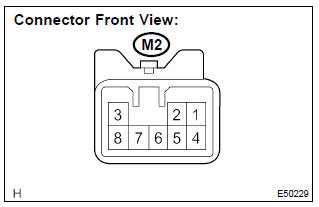

- Inspect light control switch continuity.

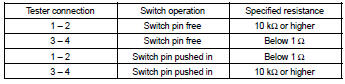

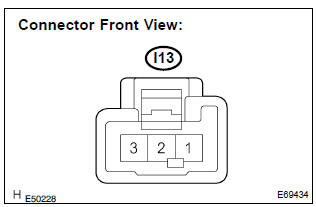

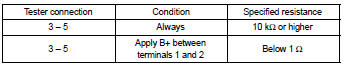

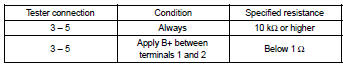

- Measure the resistance according to the value(s) in the table below.

Standard:

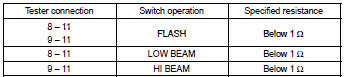

- Inspect headlight dimmer switch continuity.

- Measure the resistance according to the value(s) in the table below.

Standard:

Hint

: turn light control switch to the head position when checking ”low beam” and ”hi beam”.

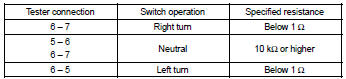

- inspect turn signal switch continuity.

- Measure the resistance according to the value(s) in the table below.

Standard:

- W/ fog light: inspect front fog light switch continuity.

- Measure the resistance according to the value(s) in the table below.

Standard:

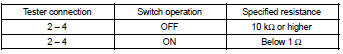

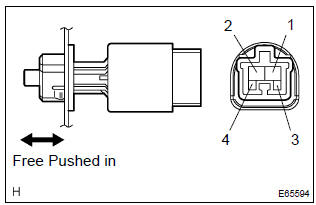

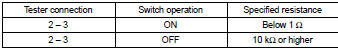

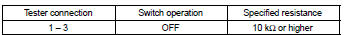

2. Back up lamp switch assy

- measure the resistance according to the value(s) in the table below.

Standard:

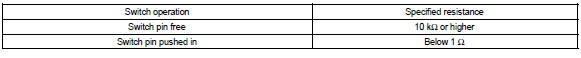

3. Stop lamp switch assy (w/o cruise control)

- measure the resistance according to the value(s) in the table below.

Standard:

4. Stop lamp switch assy (w/ cruise control)

- Measure the resistance according to the value(s) in the table below.

Standard:

5. Hazard warning signal switch assy

- Measure the resistance according to the value(s) in the table below.

Standard:

- Inspect illumination operation.

- Connect the positive (+) lead from the battery to terminal 5 and the negative (–) lead to terminal 4, then check that the illumination comes on.

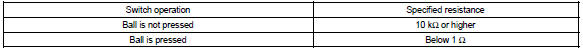

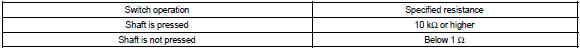

6. Front door courtesy lamp switch assy

- measure the resistance according to the value(s) in the table below.

Standard:

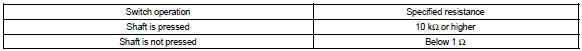

7. Rear door courtesy lamp switch assy

- measure the resistance according to the value(s) in the table below.

Standard:

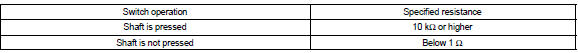

8. Luggage compartment room courtesy lamp switch assy

- measure the resistance according to the value(s) in the table below.

Standard:

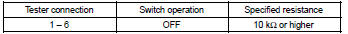

9. Map lamp assy (w/o sliding roof)

- Measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) lead from the battery to terminal 1 and the negative (–) lead to terminal 6, then check that the illumination comes on when switch operation is on position.

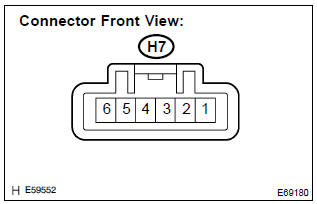

10. Map lamp assy (w/ sliding roof)

- Measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) lead from the battery to terminal 1 and the negative (–) lead to terminal 3, then check that the illumination comes on when switch operation is on position.

11. Room lamp assy no.1

- Connect the positive (+) lead from the battery to terminal 1 and the negative (–) lead to terminal 2, then check that the illumination comes on .

13. Headlamp relay

- Measure the resistance according to the value(s) in the table below.

Standard:

14. Fog lamp relay

- Measure the resistance according to the value(s) in the table below.

Standard:

15. Taillamp relay

- Measure the resistance according to the value(s) in the table below.

Standard:

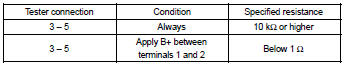

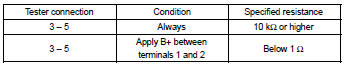

16. Headlamp dimmer relay

- Measure the resistance according to the value(s) in the table below.

Standard:

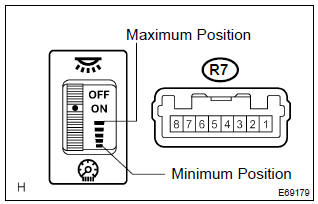

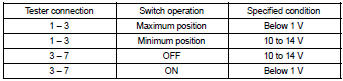

17. Light control rheostat

- Connect the connector to the rheostat and inspect the wire harness side connector from the back side as shown in the table below.

Standard:

- Inspect illumination operation.

- Connect the positive (+) lead from the battery to terminal 2 and the negative (–) lead to terminal 3, then check that the illumination comes on.

Other materials:

Replacement

Hint: components:

1. Place front wheels facing straight ahead

2. Remove front wheels

3. Remove engine under cover lh

4. Remove engine under cover rh

5. Remove exhaust pipe

6. Drain transaxle oil

7. Remove hood sub–assy

8. Remove cylinder head cover no.2

9. Remove air cleaner assy

10. R ...

Driving monitor

■ Switching the display

Items displayed can be switched by pressing the “DISP” switch.

■ Average fuel consumption

Displays the average fuel consumption since the function was reset.

• Press and hold the “DISP” switch to reset when the average fuel consumption

is display ...

If you think something is wrong

If you notice any of the following symptoms, your vehicle probably needs adjustment

or repair. Contact your Toyota dealer as soon as possible.

Visible symptoms

● Fluid leaks under the vehicle.

(Water dripping from the air conditioning after use is normal.)

● Flat-looking tires or u ...