Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Cruise control system / How to proceed with troubleshooting

Toyota Corolla (E120): How to proceed with troubleshooting

1 Vehicle brought to workshop

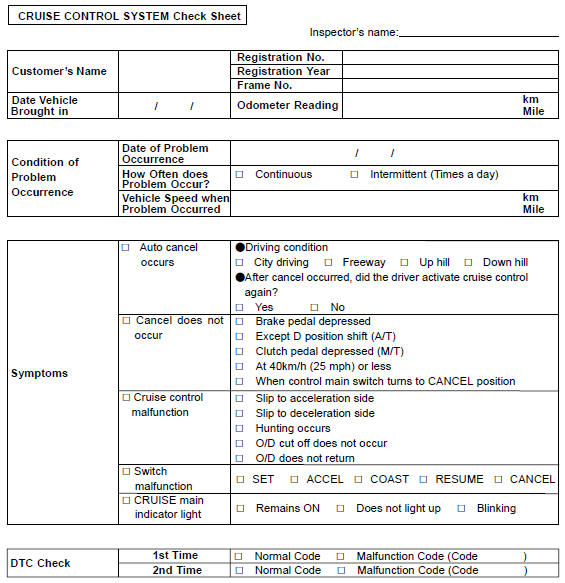

2 Customer problem analysis

3 Check and clear dtc

4 Problem symptom confirmation

5 Symptom simulation

6 Dtc check

7 Dtc chart

8 Problem symptoms table

9 Circuit inspection

10 Identification of problem

11 Parts inspection

12 Repair

13 Confirmation test

End

Customer problem analysis check

Other materials:

Inspection procedure

1 Check p/t squib(lh) circuit(airbag sensor assy center – front seat

outer belt assy lh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the seat belt pretensio ...

Driving support system

information display

■ Driving support system

information

Select to display the operational

status of the following systems:

LTA (Lane Tracing Assist)

LDA (Lane Departure Alertl)

Dynamic radar cruise control

■ Navigation system-linked

display (if equipped)

Select to display the following

navigation system-linke ...

Tire rotation

Rotate the tires in the order

shown.

Front

To equalize tire wear and extend

tire life, Toyota recommends that

tire rotation is carried out at the

same interval as tire inspection.

Vehicles with a tire pressure warning

system: Do not fail to initialize

the tire pressure warning system

after tire ...