Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Combination meter / How to proceed with troubleshooting

Toyota Corolla (E120): How to proceed with troubleshooting

1 Vehicle brought to workshop

2 Customer problem analysis

3 Problem symptom confirmation

4 Circuit inspection

5 Repair or replace

6 Confirmation test

7 End

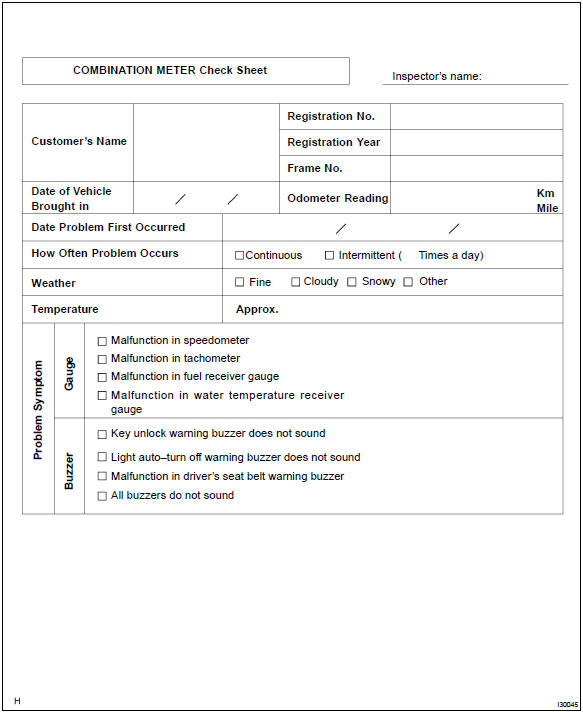

Customer problem analysis check

Other materials:

Inspection procedure

1 Check side squib(rh) circuit(airbag sensor assy center – front

seat airbag assy rh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the front seat airbag assy ...

Cd cannot be taken out

Wiring diagram

Inspection procedure

1 Check if radio auto–search functions properly

Check if the radio auto–search function properly.

Perform the auto–research of the radio and check that the

operation is normal.

Standard: malfunction disappear.

2 Press ”eject†...

Checking monitor status

Hint:

”monitor result” indicates normal or malfunction of each

component and system when judgment has done.

1. How to read data

Connect the hand–held tester to the dlc 3.

enter ”monitor result” from ”diagnosis / enhanced

obd ii / monitor info / monitor result”

on ...