Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Crankshaft position – camshaft

position correlation / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0335

|

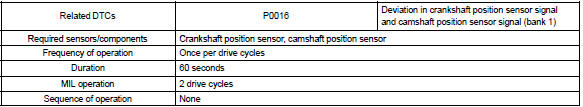

Dtc no. |

Dtc detection condition |

Trouble area |

| P0016 | Deviation in crankshaft position sensor signal and camshaft position sensor signal (2 trip detection logic) |

|

Monitor description

The ecm optimizes the valve timing using the variable valve timing (vvt) system to control the intake valve camshaft. The vvt system includes the ecm, the oil control valve (ocv) and the vvt controller. The ecm sends a target ”duty–cycle” control signal to the ocv. This control signal, applied to the ocv, regulates the oil pressure supplied to the vvt controller. The vvt controller can advance or retard the intake valve camshaft.

The ecm calibrates the valve timing of the vvt system by setting the camshaft to the maximum retard angle when the engine speed is idling. The ecm closes the ocv to retard the cam. The ecm stores this valve as ”vvt learned value” (when the difference between the target valve timing and the actual valve timing is 5 or less, the ecm learns it).

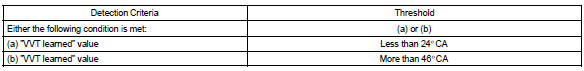

If the learned value meets both of the following conditions (”a” and ”b”), the ecm interprets this as a defect in the vvt system and set a dtc.

- ”vvt learning” value is less than 24 ca, or more than 46 ca.

- above condition continues for more than 18 seconds.

Monitor strategy

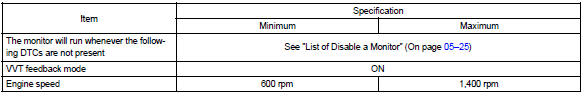

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0335

Other materials:

Uniform Tire Quality

Grading

This information has been prepared

in accordance with regulations

issued by the National

Highway Traffic Safety Administration

of the U.S. Department of

Transportation.

It provides the purchasers

and/or prospective purchasers

of Toyota vehicles with information

on uniform tire quality grading.

You ...

Inspection procedure

1 Check d squib circuit(airbag sensor assy center – horn button

assy)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the horn button assy

and the airbag sensor assy center.

for the oran ...

Inside rear view mirror

The rear view mirror's position

can be adjusted to

enable sufficient confirmation

of the rear view.

Adjusting the height of

rear view mirror

The height of the rear view mirror

can be adjusted to suit your

driving posture.

Adjust the height of the rear

view mirror by moving it up and

down.

WARNING

...