Toyota Corolla (E120) 2002–2008 Repair Manual / Emission control / Timing gear cover oil seal

Toyota Corolla (E120): Timing gear cover oil seal

Replacement

1. Remove engine under cover rh

2. Remove front wheel rh

3. Remove fan and generator v belt

- Turn the v–ribbed belt tensioner slowly clockwise and loosen it. Then, remove the fan and generator belt v and put back the v–ribbed belt tensioner little by little and fix it quietly.

4. Remove engine mounting insulator sub–assy rh

- Remove the the ps oil pump reservoir and put it aside.

- place a wooden block between the jack and engine, and set the jack. Then, remove the 4 bolts, the 2 nuts and engine mounting insulator rh.

5. Remove crankshaft pulley

- Using sst, remove the crankshaft pulley bolt.

Sst 09960–10010 (09962–01000, 09963–01000)

- remove the crankshaft pulley from the crankshaft.

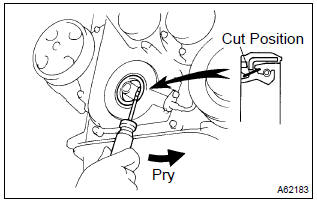

6. Remove timing gear cover oil seal

- Using a knife, cut off the oil seal lip.

- using a screwdriver with taping its tip, pry out the oil seal.

Notice

: after the removal, check if the crankshaft is not damaged.

If there is, mend it with a sandpaper (#400).

7. Install timing gear cover oil seal

- Apply mp grease to a new oil seal lip.

Notice

: keep the lip off foreign materials.

- using sst, tap in the oil seal until its surface is flush with

the timing chain cover edge.

Sst 09223–22010

N

otice

: wipe off extra grease on the crankshaft.

8. Install crankshaft pulley

- Align the pulley set key with the key groove of the pulley, and slide on the pulley.

- using sst, install the crankshaft pulley bolt.

Sst 09960–10010 (09962–01000, 09963–01000) torque: 138 nvm (1,407 Kgf·cm, 102 ft·lbf)

9. Install engine mounting insulator sub–assy rh

- Install the engine mounting insulator rh with the 4 bolts

and 2 nuts.

Torque: 52 nvm (530 Kgf·cm, 38 ft·lbf)

10. Install front wheel rh torque: 103 nvm (1050 Kgf·cm, 76 ft·lbf)

11. Check engine oil leak

Other materials:

Overhaul

1. Remove roof headlining assy

2. Remove sliding roof glass sub–assy

using a torx wrench (t25), remove the 4 screws the sliding roof

glass.

pull the glass upward to remove it.

3. Remove sliding roof weatherstrip

4. Remove sliding roof drive gear sub–assy

Notice:

...

What to do if... (Troubleshooting)

If there is a problem with the hands-free system or a Bluetooth® device, first

check the table below.

► When using the hands-free system with a

Bluetooth® device

► When registering/connecting a cellular

phone

► When making/receiving a call

► When using the p ...

Mass or volume air flow circuit

Dtc p0100 mass or volume air flow circuit

Dtc p0102 mass or volume air flow circuit

low input

Dtc p0103 mass or volume air flow circuit

high input

Circuit description

The maf (mass air flow) sensor measures the amount of air flowing through the

throttle valve. The ecm

uses this information ...