Toyota Corolla (E120): System description

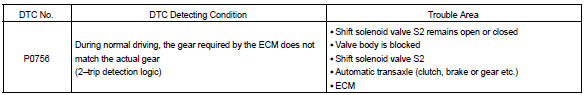

The ecm uses signals from the vehicle speed sensor and crankshaft position sensor to detect the actual gear position (1st, 2nd, 3rd or o/d gear).

Then the ecm compares the actual gear with the shift schedule in the ecm memory to detect the mechanical trouble of the shift solenoid valves, the valve body or automatic transaxle (clutch, brake or gear etc.).

Monitor description

The ecm commands gear shifts by turning the shift solenoid valves ”on/off”. According to the input shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ecm detects the actual gear position (1st, 2nd, 3rd or o/d gear position). When the gear position commanded by the ecm and the actual gear position are not same, the ecm illuminates the mil.

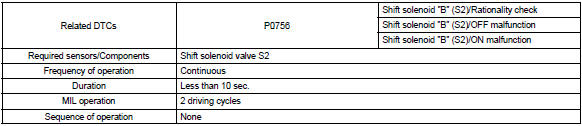

Monitor strategy

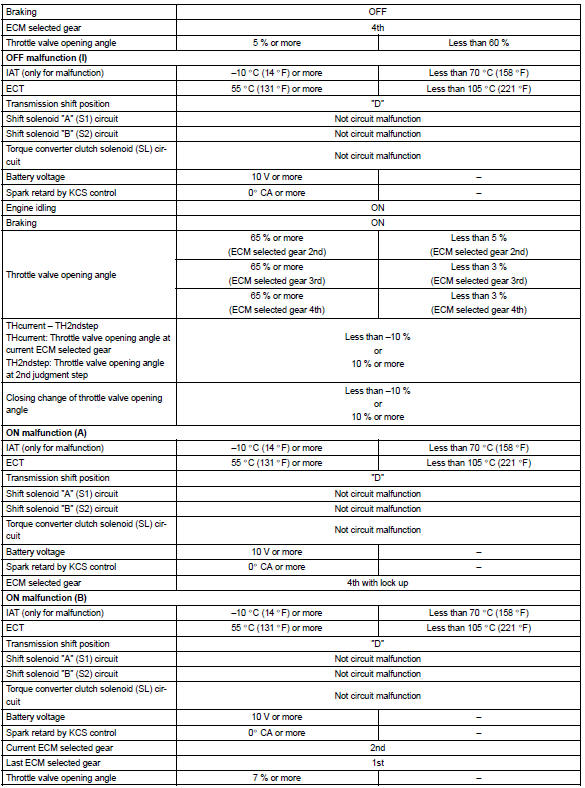

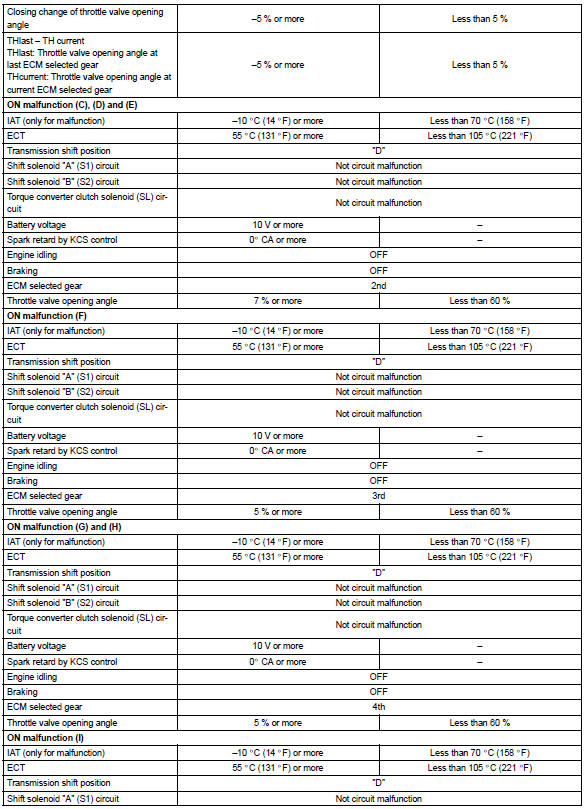

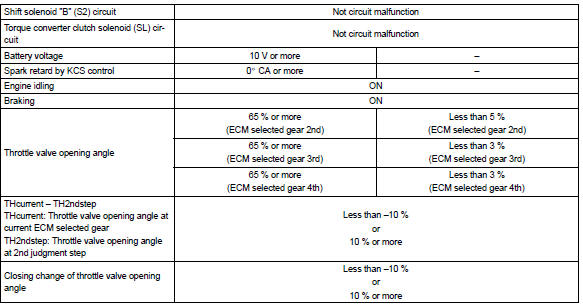

Typical enabling conditions

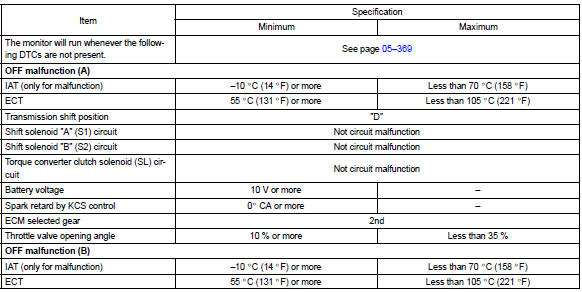

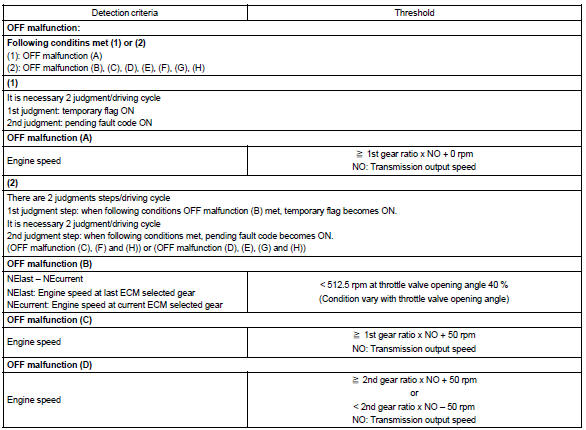

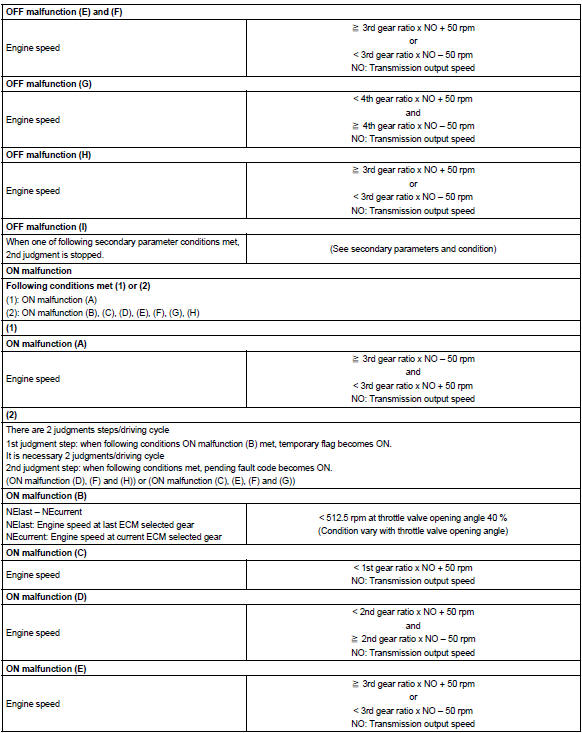

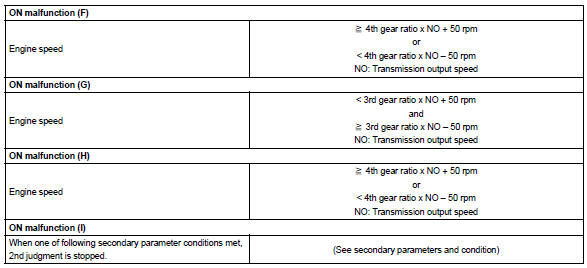

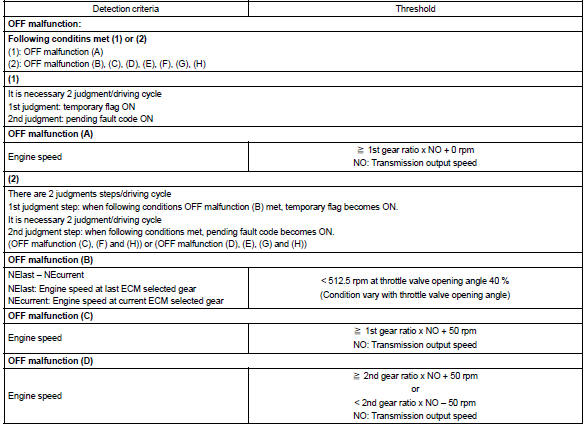

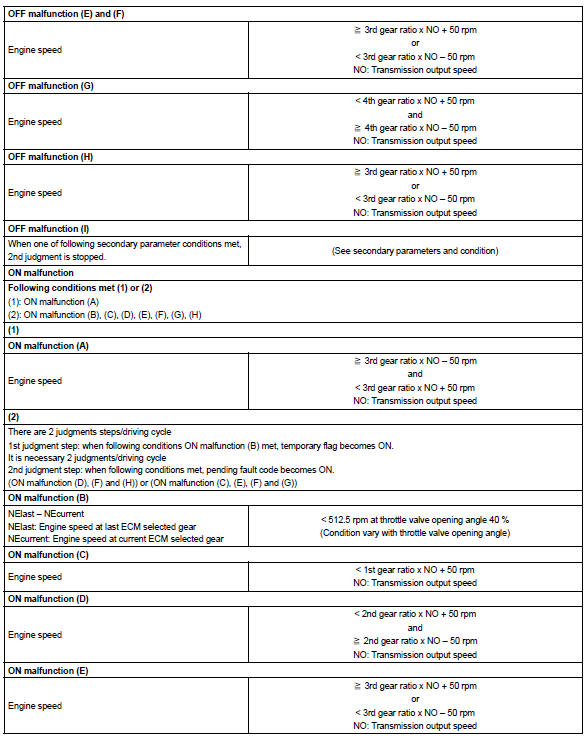

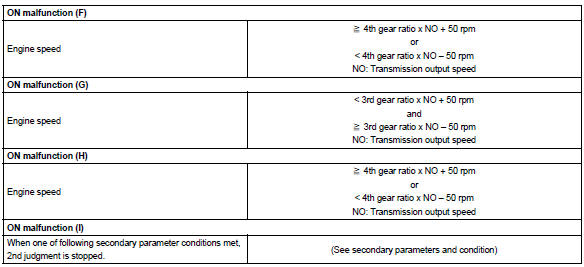

Typical malfunction thresholds

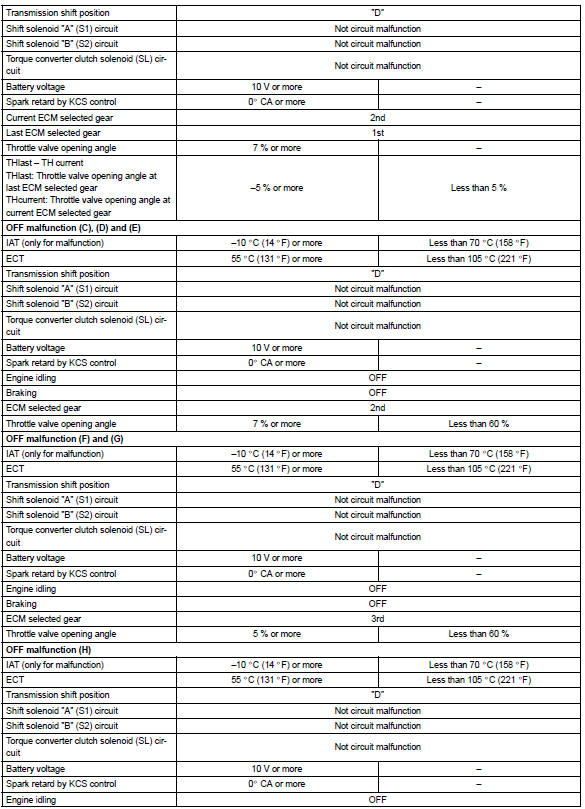

Typical malfunction thresholds

Other materials:

Tire & wheel

Wheel and tire system

Inspection

1. Inspect tire

check the tires for wear and proper inflation pressure.

Cold tire inflation pressure:

Using a dial indicator, check the tire runout.

Tire runout: 3.0 Mm (0.118 In.) Or less

2. Rotate tire

Hint:

see the illustration ...

Manual transaxle oil

On–vehicle inspection

1. Inspect transaxle oil

Stop the vehicle on the level place.

remove the transmission filler plug and gasket.

check that the oil surface is within 5 mm (0.20 In.) From the

lowest position of the inner surface of the transmission filler

plug openin ...

Body rocker panel moulding lh

Replacement

Hint:

use the same procedures for the rh side and lh side.

1. Remove body rocker panel moulding lh

Remove the 8 retainers.

using a screwdriver, remove the moulding.

Hint:

tape the screwdriver tip before use.

remove the 7 clips from the moulding.

2. Insta ...