Toyota Corolla (E120) 2002–2008 Repair Manual / Supplemental restraint system / Spiral cable sub–assy

Toyota Corolla (E120): Spiral cable sub–assy

Components

Replacement

Hint

: components:

1. Precaution

2. Disconnect battery negative terminal

3. Place front wheels facing straight ahead

- check that the front wheels are facing straight ahead.

4. Remove horn button assy

5. Remove steering wheel assy

sst 09950–50013 (09951–05010, 09952–05010, 09953–05020, 09954–05021)

6. Remove steering column cover

7. Remove spiral cable sub–assy

- Disconnect the airbag connector and the connector from the spiral cable sub–assy.

- release the 3 claws and remove the spiral cable sub– assy.

8. Inspect spiral cable sub–assy

- if the following condition is identified, replace the spiral cable sub–assy with a new one.

Condition

: scratches or cracks on the connector cracks, dents or chipping of the spiral cable sub–assy

9. Place front wheels facing straight ahead

- check that the front wheels are facing straight ahead.

10. Install spiral cable sub–assy

- set the turn signal switch in neutral position.

Notice

: make sure of the neutral position since the pin of the turn signal switch may be snapped.

- engage the 3 claws and install the spiral cable sub–assy.

Notice

: when replacing the spiral cable sub–assy with a new one, remove the lock pin before installing the handle.

- connect the airbag connector and the connector connecting to the spiral cable sub–assy.

- install the steering column cover with the 3 screws.

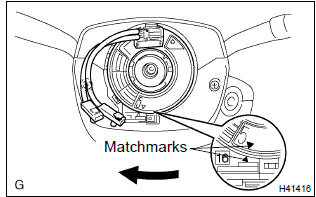

11. Center spiral cable

- check that the ignition switch is turned to off.

- check that the battery negative terminal is disconnected.

Notice

: do not start the operation for 90 seconds after removing the terminal.

- Turn the cable counterclockwise by hand until it becomes harder to turn.

Hint

: the cable will rotate about 2.5 Turns to either left or right of the center.

- Then rotate the cable clockwise about 2.5 Turns to align the marks.

12. Install steering wheel assy

torque: 50 nvm (510 kgfvcm, 37 ftvlbf)

13. Install horn button assy

torque: 8.8 Nvm (90 kgfvcm, 78 in.Vlbf)

14. Inspect horn button assy

15. Inspect srs warning light

Other materials:

Rear seats

The seatbacks of the rear seats can be folded down.

The seatbacks of the rear seats can be folded down.

1 Stow the rear outside seat belt buckles and stow the rear center seat belt

buckle as shown.

2 Pull the seatback lock release knob and fold the seatback down.

CAUTION

■When foldi ...

Replacement

1. Remove engine under cover rh

2. Remove cylinder head cover no.2

Remove the 2 screw, 3 clips and engine under cover.

3. Remove fan and generator v belt

Turn the v–ribbed belt tensioner slowly clockwise and

loosen it. Then, remove the fan and generator v belt and

put back ...

Disposal

Hint:

when scrapping vehicle equipped with an srs or disposing of a instrument panel

passenger airbag assy,

always first deploy the airbag in accordance with the procedure described below.

If any abnormality occurs

with the airbag deployment, contact the service dept. Of toyota motor sales,

...