Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Mass or volume air flow circuit

Toyota Corolla (E120): Mass or volume air flow circuit

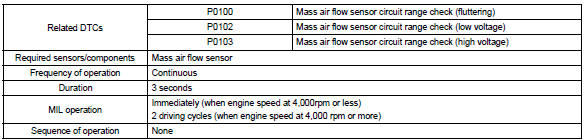

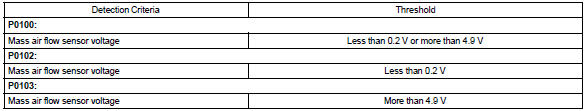

Dtc p0100 mass or volume air flow circuit

Dtc p0102 mass or volume air flow circuit low input

Dtc p0103 mass or volume air flow circuit high input

Circuit description

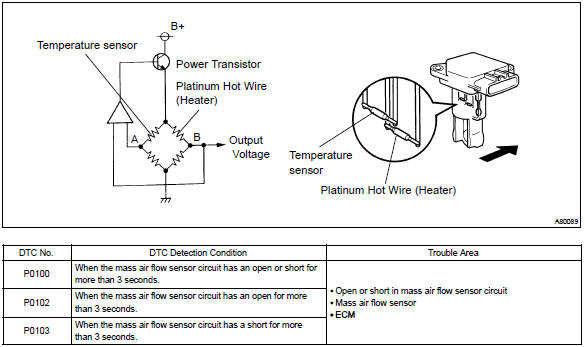

The maf (mass air flow) sensor measures the amount of air flowing through the throttle valve. The ecm uses this information to determine the fuel injection time and provide a proper air–fuel ratio. Inside the maf sensor, there is a heated platinum wire exposed to the flow of intake air.

By applying a specific current to the wire, the ecm heats this wire to a given temperature. The flow of incoming air cools the wire and an internal thermister, changing their resistance. To maintain a constant current value, the ecm varies the voltage applied to these components in the maf sensor. The voltage level is proportional to the airflow through the sensor and the ecm interprets this voltage as the intake air amount.

The circuit is constructed so that the platinum hot wire and the temperature sensor provides a bridge circuit, with the power transistor controlled so that the potential of a and b remains equal to maintain the set temperature.

Hint

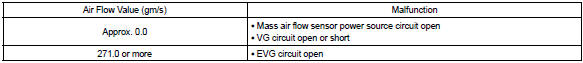

: after confirming dtc p0100, p0102 or p0103, confirm the mass air flow ratio in the ”diagnosis / enhanced obd ii / data list / all” using the hand–held tester or the obd ii scan tool.

Monitor description

If there is a defect in the sensor or an open or short circuit, the voltage level will deviate outside the normal operating range. The ecm interprets this deviation as a defect in the maf sensor and sets a dtc.

Example: when the sensor voltage output is less than 0.2 V or more than 4.9 V and if either the condition continues for more than 3 seconds.

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

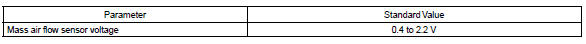

Component operating range

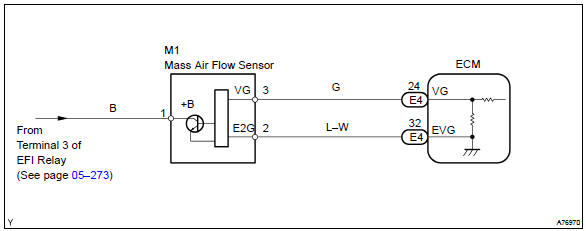

Wiring diagram

Inspection procedure

Hint

: read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

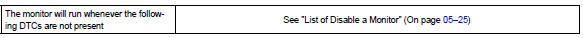

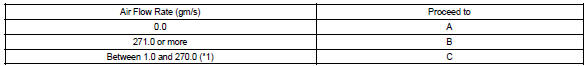

1 Read value of hand–held tester or obd ii scan tool(mass air flow rate)

- Connect the hand–held tester or the obd ii scan tool to the dlc3.

- start the engine.

- push the hand–held tester or the obd ii scan tool main switch on.

- select the item ”diagnosis / enhanced obd ii / data list / all / maf” and read its value displayed on the hand–held tester or the obd ii scan tool.

Result:

*1: The value must be changed when the throttle valve is opened or closed.

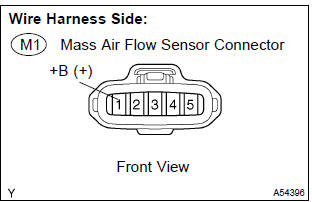

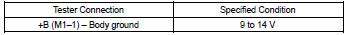

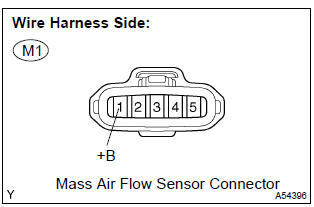

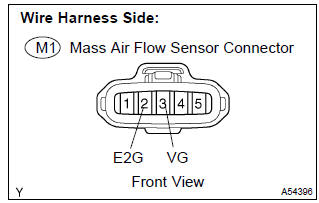

2 Inspect mass air flow sensor(power source)

- Turn the ignition switch on.

- disconnect the m1 mass air flow sensor connector.

- measure the voltage between the terminal of the wire harness side connector and body ground.

Standard:

- Reconnect the mass air flow sensor connector.

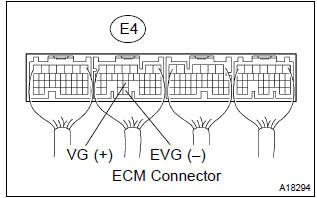

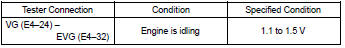

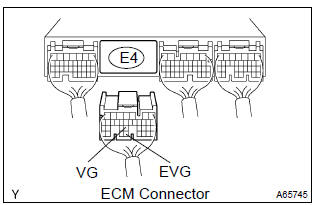

3 Inspect ecm(vg voltage)

- Start the engine.

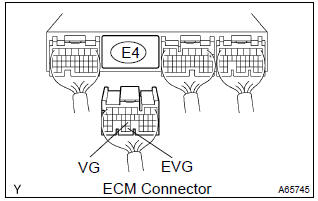

- measure the voltage between the terminals of the e4 ecm connector.

Hint

: the shift position should be p or n and the a/c switch should be turned off. Standard:

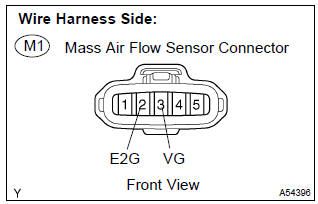

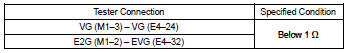

4 Check harness and connector(mass air flow sensor – ecm)

- Disconnect the m1 mass air flow sensor connector.

- disconnect the e4 ecm connector.

- check the resistance between the wire harness side connectors.

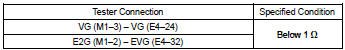

Standard (check for open):

Standard (check for short):

- Reconnect the mass air flow sensor connector.

- reconnect the ecm connector.

Replace mass air flow sensor

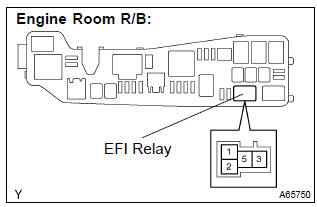

5 Check harness and connector(mass air flow sensor – efi relay)

- Remove the efi relay from the engine room r/b.

- disconnect the m1 mass air flow sensor connector.

- check the resistance between the wire harness side connectors.

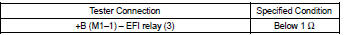

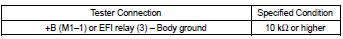

Standard (check for open):

Standard (check for short):

- Reconnect the mass air flow sensor connector.

- reinstall the efi relay.

Check for ecm power source circuit

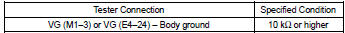

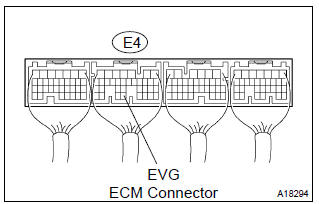

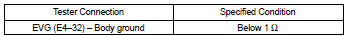

6 Inspect ecm(sensor ground)

- Check the resistance between the terminals of the e4 ecm connector.

Standard:

7 Check harness and connector(mass air flow sensor – ecm)

- Disconnect the m1 mass air flow sensor connector.

- disconnect the e4 ecm connector.

- check the resistance between the wire harness side connectors.

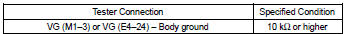

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the mass air flow sensor connector.

Replace mass air flow sensor

Other materials:

Inspection

1. Thermostat

Hint:

the thermostat is numbered with the valve opening temperature.

Immerse the thermostat in water and gradually heat the

water.

check the valve opening temperature.

Valve opening temperature:

80 to 84 c (176 to 183 f)

Hint:

if the valve opening temperatur ...

Engine coolant

The coolant level is satisfactory if it is between the “F” and “L” lines on the

reservoir when the engine is cold.

1 Reservoir cap

2 “F” line

3 “L” line

If the level is on or below the “L” line, add coolant up to the “F” line.

■Coolant selection

Only use “To ...

How to proceed with troubleshooting

1 Vehicle brought to workshop

2 Customer problem analysis

3 Check and clear dtcs and freeze frame data

4 Problem symptom confirmation

Symptom does not occur: go to

step 5

Symptom occurs: go to step 6

5 Symptom simulation

6 Dtc check

There is no

output: go to step 7

There is outp ...