Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p squib (2nd step) circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

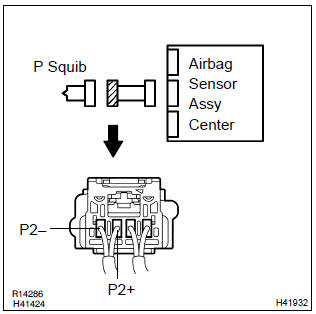

1 Check p squib circuit(airbag sensor assy center – instrument panel passenger airbag assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the instrument panel passenger airbag assy.

- release the airbag activation prevention mechanism of the connector (on the airbag sensor assy center side) between the airbag sensor assy center and the instrument panel passenger airbag assy .

- for the connector (on the instrument panel passenger airbag

assy side) between the airbag sensor assy center

and the instrument panel passenger airbag assy, measure

the resistance between p2+ and p2–.

Ok: resistance: 1 mw or higher

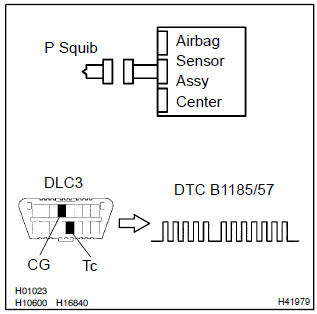

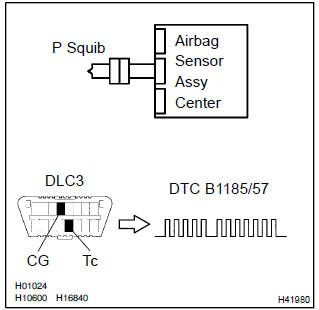

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1185/57 is not output.

Hint

: codes other than code b1185/57 may be output at this time, but they are not relevant to this check.

3 Check p squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the instrument panel passenger airbag assy connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1185/57 is not output.

Hint

: codes other than code b1185/57 may be output at this time, but they are not relevant to this check.

Use simulation method to check

Other materials:

Bluetooth® audio/phone

The following can be performed using Bluetooth® wireless communication:

■ Bluetooth® audio

The Bluetooth® audio system enables you to enjoy music played on a portable

player from the vehicle speakers via wireless communication.

This audio system supports Bluetooth®, a wireless data sy ...

Disposal

1. Dispose shock absorber assy rear lh

Fully extend the shock absorber rod.

using a drill, make a hole in the cylinder as shown in the

illustration to discharge the gas inside.

Caution:

when drilling, chips may fly out, work carefully.

The gas is colorless, odorless and no ...

Tire information

Typical tire symbols

► Full-size tire

► Compact spare tire

1 Tire size

2 DOT and Tire Identification Number (TIN)

3 Uniform tire quality grading

For details, see “Uniform Tire Quality Grading” that follows.

4 Location of treadwear indicators

5 Tire ply composition and ma ...