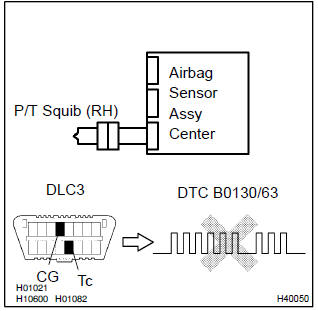

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p/t squib (rh) circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

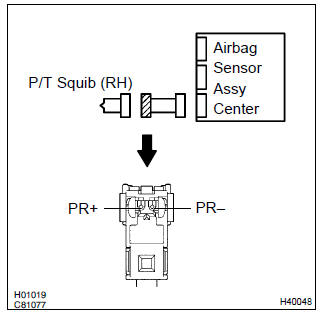

1 Check p/t squib(rh) circuit(airbaga sensor assy center – front seat outer belt assy rh)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor

assy center and the seat belt pretensioner (rh).

Hint

: make sure that the connector is not damaged (the lock button is not disengaged, or the claw of the lock is not deformed or damaged). If the damage is found, replace the wire harness.

- release the airbag activation prevention mechanism of the connector (on the airbag sensor assy center side) between the airbag sensor assy center and the seat belt pretensioner (rh) .

- for the connector (on the seat belt pretensioner side) between

the airbag sensor assy center and the seat belt pretensioner

(rh), measure the resistance between pr+

and pr–.

Ok: resistance: 1 mΩ or higher

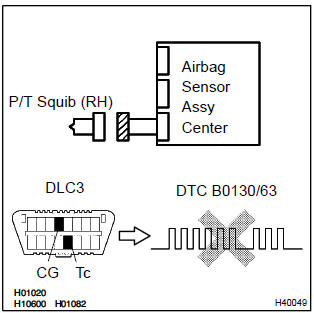

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0130/63 is not output.

Hint

: codes other than code b0130/63 may be output at this time, but they are not relevant to this check.

3 Check p/t squib (rh)

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the seat belt pretensioner (rh) connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0130/63 is not output.

Hint

: codes other than code b0130/63 may be output at this time, but they are not relevant to this check.

Use simulation method to check

Other materials:

Inspection procedure

1 Check security indicator light

Set the system in 30 seconds after filliping the security indicator to

check if the alarm is triggered.

2 Check glass breakage sensor ecu (glass breakage sensor)

Check the continuity and voltage of the glass breakage

sensor ecu, as shown in th ...

Inspection

1. Spark plug

Notice:

never use a wire brush for cleaning.

Never attempt to adjust the electrode gap on used

spark plug.

Spark plug should be replaced every 192,000 km

(120,000 miles).

Clean the spark plugs.

Air pressure: below 588 kpa (6.0 Kg/cm2, 85 psi)

duration: 20 sec ...

Warning lights and indicators

The warning lights and indicators on the instrument cluster,

center panel, overhead console and outside rear view mirrors inform the driver

of the status of the vehicle's various systems.

Warning lights and indicators displayed on the instrument

cluster

For the purpose of explanation, the followin ...