Toyota Corolla (E120): Inspection procedure

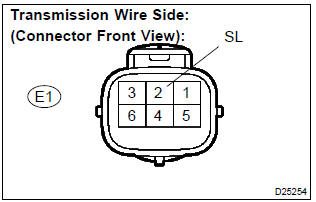

1 Inspect transmission wire(sl)

- Disconnect the transmission wire connector from the transaxle.

- measure the resistance according to the value(s) in the table below.

Standard:

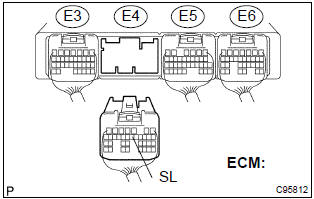

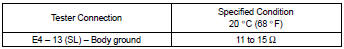

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission wire connector.

- disconnect the ecm connector.

- measure the resistance according to the value(s) in the table below.

Standard:

Replace ecm

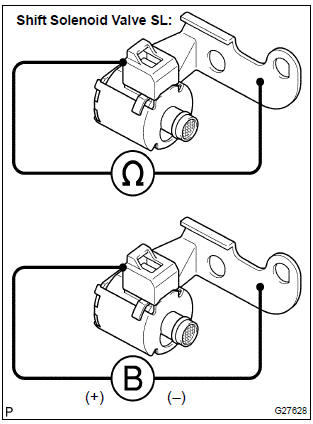

3 Inspect shift solenoid valve(sl)

- Remove the shift solenoid valve sl.

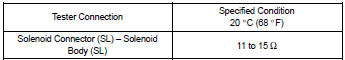

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead to the solenoid connector terminal, and the negative (–) battery lead to the solenoid body for checking the solenoid valve operation.

Standard: the solenoid valve makes an operating noise.

Repair or replace transmission wire

Other materials:

Inspection procedure

1 Inspect terminal voltage(idl)

Remove the cruise control ecu assy with connector still

connected.

disconnect the ecm connector.

turn the ignition switch to on.

measure voltage between terminal 13 (idl) of cruise control

ecu assy connector and body ground when the ...

Listing the registered portable players

Select “List Audio” using .

The list of registered portable players will be displayed.

● Connecting the registered portable player to the audio system

1 Select the name of the portable player to be connected using

.

2 Select “Select” using .

● Deleting the registered ...

Overhaul

1. Remove manual transmission filler plug

Remove the manual transmission filler plug and gasket

from the manual transmission case.

2. Remove drain (mtm) plug sub–assy

Remove the drain (mtm) plug sub–assy and gasket from

the manual transmission case.

3. Remove speedomete ...