Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Fuel pump control circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hand–held tester:

1 Perform active test by hand–held tester(operation of circuit opening relay)

- Connect the hand–held tester to the dlc3.

- turn the ignition switch on and push the hand–held tester main switch on.

- select the item ”diagnosis / enhanced obd ii / active test / fuel pump / spd”.

- check the relay operation while operating it with the hand–held tester.

Standard: operating noise can be heard from the relay.

2 Inspect ecm power source circuit

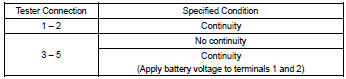

3 Inspect circuit opening relay

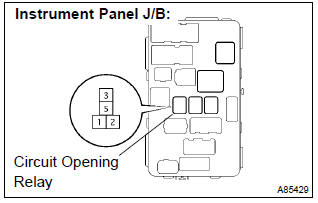

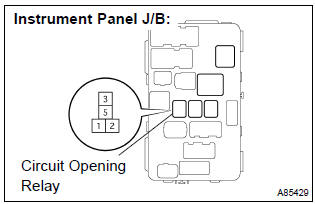

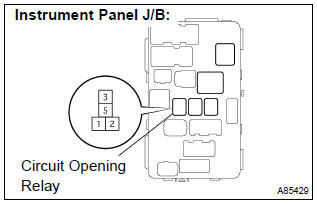

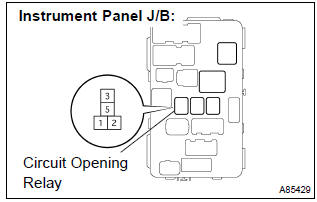

- Remove the circuit opening relay from the instrument panel j/b.

- check for continuity in the circuit opening relay.

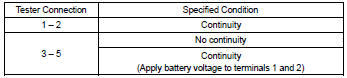

Standard:

- Reinstall the circuit opening relay.

4 Inspect ecm(fc voltage)

- Turn the ignition switch on.

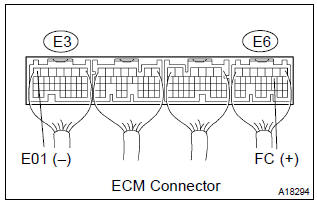

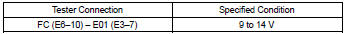

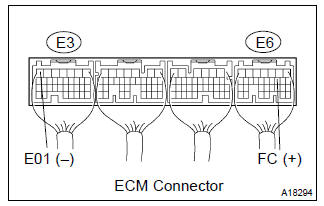

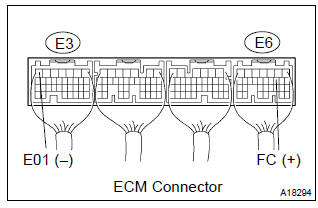

- measure the voltage between the terminals of the e3 and e6 ecm connectors.

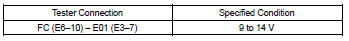

Standard:

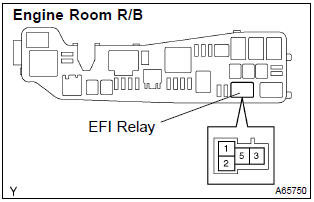

5 Check harness and connector(efi relay – circuit opening relay)

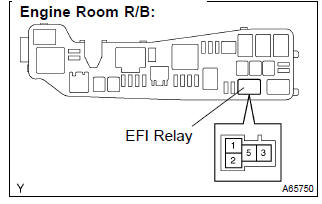

- Remove the efi relay from the engine room r/b.

- remove the circuit opening relay from the instrument panel j/b.

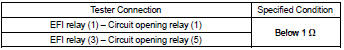

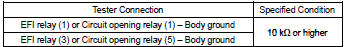

- check the resistance between the wire harness side connectors.

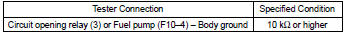

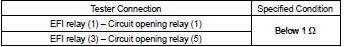

Standard (check for open):

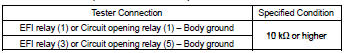

Standard (check for short):

- Reinstall the circuit opening relay.

- reinstall the efi relay.

Replace ecm

6 Inspect fuel pump

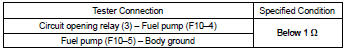

7 Check harness and connector(circuit opening relay – fuel pump, fuel pump – body ground)

- Remove the circuit opening relay from the instrument panel j/b.

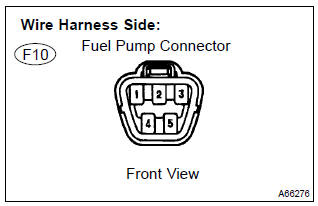

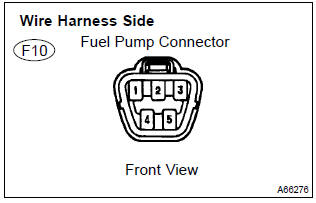

- disconnect the f10 fuel pump connector.

- check the resistance between the wire harness side connectors.

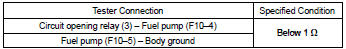

Standard (check for open):

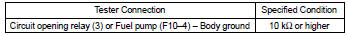

Standard (check for short):

- Reconnect the fuel pump connector.

- reinstall the circuit opening relay.

Replace ecm

Obd ii scan tool (excluding hand–held tester):

1 Check operation of fuel pump

- Turn the ignition switch on.

- connect between terminals fc and e01 of the ecm connector.

- check for fuel pressure in the fuel inlet hose when it is

pinched off.

Result: there is pressure in fuel inlet hose.

Hint

: at this time, you will hear the fuel flowing sound.

2 Inspect ecm power source circuit

3 Inspect circuit opening relay

- Remove the circuit opening relay from the instrument panel j/b.

- check for continuity in the circuit opening relay.

Standard:

- Reinstall the circuit opening relay.

4 Inspect ecm(fc voltage)

- Turn the ignition switch on.

- measure the voltage between the terminals of the e3 and e6 ecm connectors.

Standard:

5 Check harness and connector(efi relay – circuit opening relay)

- Remove the efi relay from the engine room r/b.

- remove the circuit opening relay from the instrument panel j/b.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reinstall the circuit opening relay.

- reinstall the efi relay.

Replace ecm

6 Inspect fuel pump

7 Check harness and connector(circuit opening relay – fuel pump,fuel pump – body ground)

- Remove the circuit opening relay from the instrument panel j/b.

- disconnect the f10 fuel pump connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the fuel pump connector.

- reinstall the circuit opening relay.

Replace ecm

Other materials:

Stabilizer bar front

Replacement

Hint: components:

1. Remove front wheel

2. Remove front stabilizer link assy lh

Remove the 2 nuts and stabilizer bar link.

Hint:

if the ball joint turns together with the nut, use a hexagon

wrench (6 mm) to hold the stud.

3. Remove front stabilizer link assy rh

Hint:

...

Listening to a USB memory device

Connecting a USB memory device enables you to enjoy music from the vehicle

speakers.

Touch “USB” on the audio source selection screen.

Connecting a USB memory device

Audio control screen

Pressing the “AUDIO” button displays the audio control screen from any screens

of the selected so ...

Replacement

1. Remove engine under cover rh

2. Remove fan and generator v belt

3. Remove generator assy

Disconnect the wire clamp from the wire clip on the rectifire

end frame.

remove the rubber cap and nut, and disconnect the alternator

wire.

disconnect the alternator connecto ...