Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position sensor ”a”

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

: read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

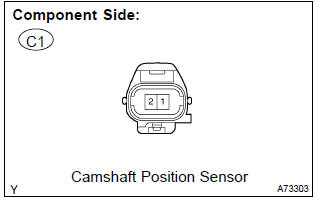

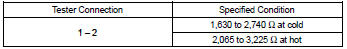

1 Inspect camshaft position sensor(resistance)

- Measure the resistance between the terminals of camshaft position sensor connector.

Standard:

Notice

: ”cold” and ”hot” shown above mean the temperature of the coils themselves. ”Cold” is from –10 c (14 f) to 50 c (122 f) and ”hot” is from 50 c (122 f) to 100 c (212 f).

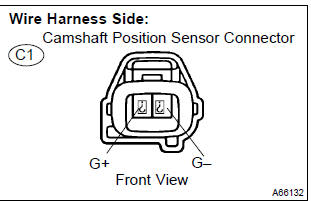

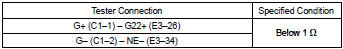

2 Check harness and connector(camshaft position sensor – ecm)

- Disconnect the c1 camshaft position sensor connector.

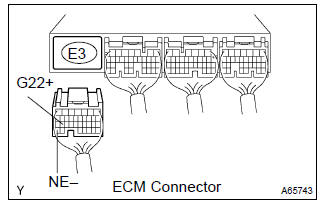

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

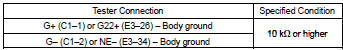

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the camshaft position sensor connector.

3 Check sensor installation(camshaft position sensor)

- Check the camshaft position sensor installation.

4 Check camshaft timing gear assy(teeth of plate)

- Check the teeth of the signal plate.

Replace ecm

Other materials:

Optimal use of the multimedia system

On the “Sound Settings” screen, sound quality (Treble/Mid/ Bass), volume balance

can be adjusted.

How to adjust the sound settings and sound quality

1 2 3 Select “-” or “+” to adjust the treble, mid or bass to a level between

-5 and 5.

4 5 Select “Front” or “Rear” to adjus ...

Listening to an iPod

Connecting an iPod enables you to enjoy music from the vehicle speakers. Press

until “iPod” is displayed.

Connecting an iPod

Control panel

1 Power

2 Volume

3 Fast-forward or reverse

4 Repeat play

5 Shuffle playback

6 Select an iPod menu/song or display song list

7 Displays text mess ...

Seat belts

Make sure that all occupants

are wearing their seat

belts before driving the

vehicle.

WARNING

Observe the following precautions

to reduce the risk of injury in the

event of sudden braking, sudden

swerving or an accident.

Failure to do so may cause death

or serious injury.

■Wearing a seat belt

E ...