Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position ”a” –timing over / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

| Advanced timing over (valve timing is out of specified range) | P0011 |

| Retarded timing over (valve timing is out of specified range) | P0012 |

- If dtc p0011 or p0012 is displayed, check the vvt system circuit.

- Read freeze frame data using the hand–held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

Hand–held tester:

1 Check valve timing(check for loose and jumped tooth of timing chain)

2 Perform active test by hand–held tester(operate ocv)

- Connect the hand–held tester to the dlc3.

- start the engine and warm it up.

- turn the ignition switch on and push the hand–held tester main switch on.

- select the item ”diagnosis / enhanced obd ii / active test / vvt ctrl b1”.

- check the engine speed when operating the ocv by the hand–held tester.

Standard:

3 Check if dtc outputs reoccur

- Clear the dtcs.

- Operate the hand–held tester to erase the codes, or disconnect the battery terminal or remove the efi fuse for more than 60 seconds.

- start and warm up the engine.

- drive the vehicle around for 10 minutes or more.

- read output dtcs using the hand–held tester.

Standard: no dtc output.

Hint

: *: dtc p0011 or p0012 is output when a foreign object in engine oil is caught in some part of the system.

These codes will stay registered even if the system returns to normal after a short time. These foreign objects are then captured by the oil filter, thus eliminating the source of the problem.

- reconnect the battery terminal or install the efi fuse.

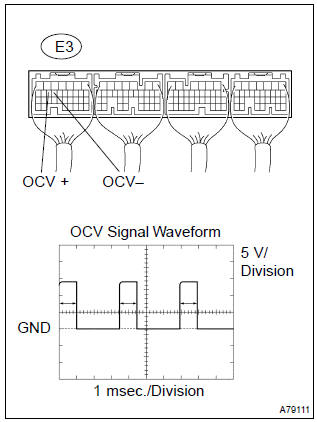

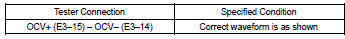

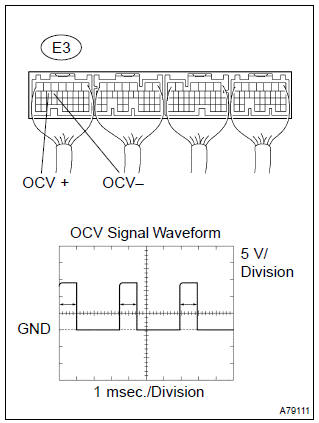

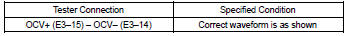

4 Inspect ecm(ocv signal)

- Inspect using the oscilloscope.

- during idling, check the waveform between the terminals of the e3 ecm connector.

Standard:

5 Inspect oil control valve filter

6 Inspect camshaft timing oil control valve assy(ocv)

7 Replace camshaft timing oil control valve assy(ocv)

8 Inspect camshaft timing gear assy

9 Replace camshaft timing gear assy

10 Check for blockage(ocv, oil check valve and oil hole)

11 Check if dtc outputs reoccur

- Clear the dtcs.

- Operate the hand–held tester to erase the codes, or disconnect the battery terminal or remove the efi fuse for more than 60 seconds.

- start and warm up the engine.

- drive the vehicle around for 10 minutes or more.

- read output dtc using the hand–held tester.

Standard: no dtc output.

Hint

: *: dtc p0011 or p0012 is output when a foreign object in engine oil is caught in some part of the system.

These codes will stay registered even if the system returns to normal after a short time. These foreign objects are then captured by the oil filter, thus eliminating the source of the problem.

- reconnect the battery terminal or install the efi fuse.

Obdii scan tool (excluding hand–held tester):

Replace ecm

1 Check valve timing(check for loose and jumped tooth of timing chain)

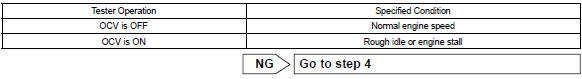

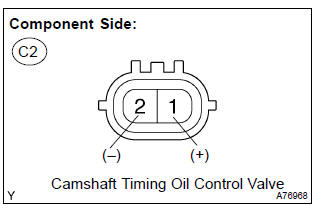

2 Check operation of ocv

- Start the engine.

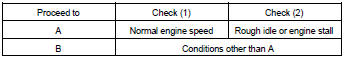

- check the engine speed at (1) and (2).

- Disconnect the c2 camshaft timing oil control valve connector.

- Apply battery positive voltage between the terminals of the camshaft timing oil control valve.

Result:

- Reconnect the camshaft timing oil control valve connector.

3 Check if dtc outputs reoccur(check if dtc output recurs)

- Clear the dtcs.

- Operating the obd ii scan tool to erase the codes, or disconnect the battery terminal or remove the efi fuse for more than 60 seconds.

- start and warm up the engine.

- drive the vehicle around for 10 minutes or more.

- read output dtcs using the obd ii scan tool.

Standard: no dtc output.

Hint

: *: dtc p0011 or p0012 is output when a foreign object in engine oil is caught in some part of the system.

These codes will stay registered even if the system returns to normal after a short time. These foreign objects are then captured by the oil filter, thus eliminating the source of the problem.

4 Inspect ecm(ocv signal)

- Inspect using the oscilloscope.

- during idling, check the waveform between the terminals of the e3 ecm connector.

Standard:

5 Inspect oil control valve filter

6 Inspect camshaft timing oil control valve assy(ocv)

7 Replace camshaft timing oil control valve assy(ocv)

8 Inspect camshaft timing gear assy

9 Replace camshaft timing gear assy

10 Check for blockage(ocv, oil check valve and oil hole)

11 Check if dtc outputs reoccur

- Clear the dtcs.

- Operate the obd ii scan tool to erase the codes, or disconnect the battery terminal or remove the efi fuse for more than 60 seconds.

- start and warm up the engine.

- drive the vehicle around for 10 minutes or more.

- read output dtcs using the obd ii scan tool.

Standard: no dtc output.

Hint

: *: dtc p0011 or p0012 is output when a foreign object in engine oil is caught in some part of the system.

These codes will stay registered even if the system returns to normal after a short time. These foreign objects are then captured by the oil filter, thus eliminating the source of the problem.

- reconnect the battery terminal or install the efi fuse.

Replace ecm

Other materials:

Capacity and distribution

Cargo capacity depends on the total weight of the occupants.

(Cargo capacity) = (Total load capacity) — (Total weight of occupants)

Steps for Determining Correct Load Limit —

(1) Locate the statement “The combined weight of occupants and cargo should never

exceed XXX kg or XXX lbs.” on ...

Description

When troubleshooting obd ii vehicles, the only difference

from the usual troubleshooting procedure is that you

need to connect the vehicle to the obd ii scan tool complying

with sae j1978 or the hand–held tester, and read

various data output from the vehicle’s ecm.

Obd ii regulation ...

Stabilizer bar front

Replacement

Hint: components:

1. Remove front wheel

2. Remove front stabilizer link assy lh

Remove the 2 nuts and stabilizer bar link.

Hint:

if the ball joint turns together with the nut, use a hexagon

wrench (6 mm) to hold the stud.

3. Remove front stabilizer link assy rh

Hint:

...