Toyota Corolla (E120): Hydraulic test

1. Perform hydraulic test

- Measure the line pressure.

Notice

:

- Do the test at normal operation atf temperature 50 to 80 °c (122 to 176 °f).

- The line pressure test should always be carried out in pairs. One technician should observe the conditions of wheels or wheel stopper outside the vehicle while the other is doing the test.

- Be careful to prevent sst’s hose from interfering with the exhaust pipe.

- Warm up the atf.

- Remove the test plug on the transaxle case front left

side and connect sst.

Sst 09992–00095 (09992–00231, 09992–00271)

- fully apply the parking brake and chock the 4 wheels.

- Connect an obd ii scan tool or hand–held tester to the dlc3.

- Start the engine and check the idling speed.

- Keep your left foot pressed firmly on the brake pedal and shift into the d position.

- Measure the line pressure when the engine is idling.

- Depress the accelerator pedal all the way down.

Quickly read the highest line pressure when the engine speed reaches the stall speed.

- Do the test in the r position in the same way.

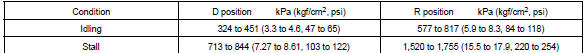

Specified line pressure:

Evaluation:

|

Problem |

Possible cause |

| If the measured values at all positions are higher |

|

| If the measured values at all positions are lower |

|

| If pressure is low in the d position only |

|

| If pressure is low in the r position only |

|

Other materials:

Ecm (1zz–fe)

Replacement

1. Disconnect battery negative terminal

2. Remove glove compartment door assy

3. Remove ecm

Remove the 2 clips using a clip remover. Then, open the

cover.

Disconnect the 4 ecm connectors.

remove the wire harness from the wire harness clamp.

Remove the 2 ...

Shifting the shift lever

Vehicles without a smart key system:

While the engine switch is in the “ON” position, depress the brake pedal and

move the shift lever.

Vehicles with a smart key system: While the engine switch is in IGNITION ON mode,

depress the brake pedal and move the shift lever.

When shifting the ...

Thermostat

Replacement

1. Remove engine under cover rh

2. Drain coolant

3. Remove fan and generator v belt

4. Remove generator assy

Disconnect the wire clamp from the wire clip on the rectifire

end frame.

remove the rubber cap and nut, and disconnect the alternator

wire.

d ...