Toyota Corolla (E120) 2002ŌĆō2008 Repair Manual / Diagnostics / Cruise control system / How to proceed with troubleshooting

Toyota Corolla (E120): How to proceed with troubleshooting

1 Vehicle brought to workshop

2 Customer problem analysis

3 Check and clear dtc

4 Problem symptom confirmation

5 Symptom simulation

6 Dtc check

7 Dtc chart

8 Problem symptoms table

9 Circuit inspection

10 Identification of problem

11 Parts inspection

12 Repair

13 Confirmation test

End

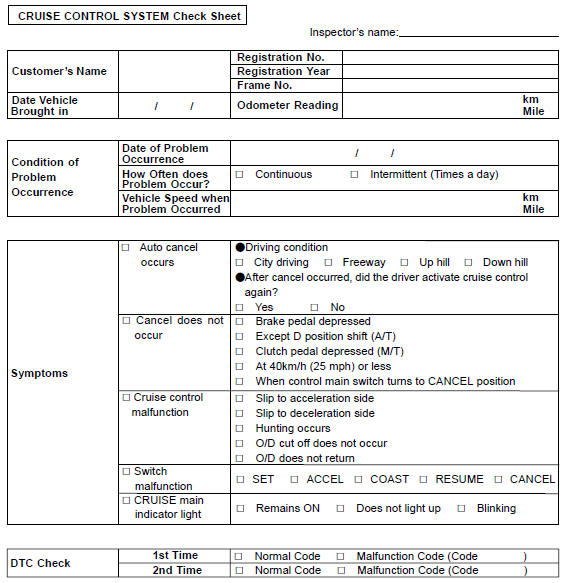

Customer problem analysis check

Other materials:

Parking brake

The parking brake can be

set or released automatically

or manually.

In automatic mode, the

parking brake can be set or

released automatically

according to shift lever

operation.

Also, even in automatic

mode, the parking brake can

be set or released manually.

Operating instructions

Ō¢Ā Using the ma ...

Driving tips

Winter driving tips

Carry out the necessary preparations and inspections before driving the vehicle

in winter. Always drive the vehicle in a manner appropriate to the prevailing weather

conditions.

Preparation for winter

● Use fluids that are appropriate to the prevailing outside temper ...

Using the steering wheel switches

The steering wheel switches can be used to operate a connected cellular phone.

Operating a telephone using the steering wheel switches

■ Steering wheel switches on the right hand side

1 Off hook switch

ŌĆó Make a call

ŌĆó Receive a call

ŌĆó Display ŌĆ£PhoneŌĆØ screen

2 On hook switch

Ō ...